Research progress on preparation and properties of ultra-high temperature ceramic matrix composites

The improvement of a country’s national defense strength is inseparable from the development of aerospace technology and the improvement of weapons and equipment. Hypersonic aircraft is becoming one of the research focuses of various countries. As the aircraft is often in a harsh working environment of ultra-high temperature, large heat flow, strong erosion, and high load, thermal protection components are indispensable for the protection of the aircraft. The ultra-high temperature materials used in the manufacture of thermal protection components have excellent properties such as high strength, high temperature resistance, oxidation resistance, and thermal shock resistance. The main applications are refractory metals and their alloys, CC composite materials, C-SiC composite materials and ceramic matrix Composite materials. Studies have shown that the density of ultra-high temperature ceramic matrix composites (UHTCMCs) is much lower than that of refractory metals, and can withstand higher temperatures. The oxidation and ablation resistance in high-temperature aerobic environments is also better than that of CC and C-SiC composites, so ultra-high temperature Ceramic matrix composites are considered to be the most promising materials for the manufacture of thermal protection components for spacecraft. At present, the research on ultra-high temperature ceramic matrix composites is still in the basic research stage, and the focus is on the preparation of materials, toughening technology, the improvement of high temperature oxidation and ablation resistance, and the improvement of thermal shock resistance.

1 Ultra-high temperature ceramic matrix composite materials

Ultra-high temperature ceramic matrix composite materials refer to high temperature structural materials that can maintain stable physical and chemical properties in a high temperature environment of 2000 ℃ and above, and are based on ceramic phases. They have low density, wear resistance, excellent high temperature physical properties, and thermochemical stability. Outstanding advantages such as good performance and good thermal shock resistance. The minimum operating temperature of ultra-high temperature ceramic matrix composite materials should be higher than its operating temperature in the air (1600 ℃). In practical applications, the requirements for the operating temperature of ultra-high speed aircraft are higher, so 2000 ℃ has been listed as ultra-high temperature materials. Temperature limit. Commonly used materials are high melting point carbides, borides, nitrides and their composite materials. At present, the more widely studied ultra-high temperature ceramic matrix composite materials mainly include three major systems, namely carbide ceramic matrix composite materials, boride ceramic matrix composite materials and continuous fiber toughened ceramic matrix composite materials.

1.1 Carbide ceramic matrix composites

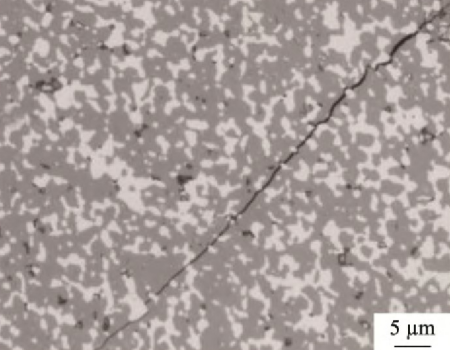

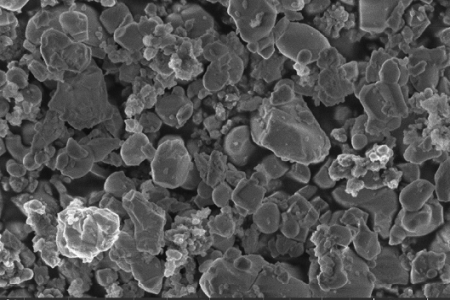

Ultra-high temperature carbide ceramics mainly include zirconium carbide (ZrC), hafnium carbide (HfC), tantalum carbide (TaC), titanium carbide (TiC), etc., with high melting point, high temperature strength, excellent electrical and thermal conductivity, and good thermal shock resistance However, due to its brittleness and insufficient oxidation resistance, silicon carbide (SiC), zirconium boride (ZrB2), zirconium oxide (ZrO2), molybdenum silicide (MoSi2), molybdenum (Mo) metal, graphite are often added (Cg) and other particles enhance its mechanical properties, improve its oxidation resistance and sintering properties. Common carbide ceramic matrix composite materials include ZrC-SiC, ZrC-ZrB2, ZrC-ZrO2, ZrC-MoSi2, ZrCMo, ZrC-SiC-Cg, HfC-SiC, TaC-SiC, TiC-SiC, etc.

1.2 Boride ceramic matrix composites

Ultra-high temperature boride ceramics mainly include zirconium boride (ZrB2), hafnium boride (HfB2), tantalum boride (TaB2) and titanium boride (TiB2). There are strong covalent bonds in ultra-high temperature boride ceramics, which have the advantages of high melting point, high strength, high thermal and electrical conductivity, and low evaporation rate. However, the strong covalent bond characteristics make it difficult to sinter and densify the material. The high temperature oxidation resistance of the material also needs to be improved.

ZrB2 and HfB2 are the most widely studied ultra-high temperature boride ceramics. By adding SiC to prepare ZrB2-SiC and HfB2-SiC composite materials, a higher binary eutectic temperature can be obtained, and the mechanical and oxidation resistance of the material can be improved. Jin et al. studied the oxidation behavior of ZrB2-SiC-Cg composites under low oxygen partial pressure, using X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), scanning electron microscope (SEM) and X-ray energy dispersion Spectroscopy (EDS) analyzes the microscopic composition of the oxidized sample. The results show that low oxygen partial pressure has a significant effect on the phase composition of the oxide layer surface and the microstructure of the oxide layer. Higher oxygen partial pressure accelerates the oxidation behavior of ZrB2-SiC-Cg composites.

1.3 Continuous fiber toughened ceramic matrix composites

Continuous fiber toughened ceramic matrix composites refer to ultra-high temperature ceramics or multiphase ceramics as the matrix, such as ZrC, ZrB2, HfC, HfB2, TaC, ZrC-SiC, ZrB2-SiC, HfB2-SiC, ZrB2-ZrC-SiC, etc. , With high temperature resistant fibers as reinforcements, such as carbon fiber (Cf), silicon carbide fiber (SiCf), etc., ultra-high temperature composite materials with high strength, high toughness, low density, high temperature resistance and other excellent properties are formed.

The high temperature resistant fiber has low density, high strength and good high temperature performance. Among them, Cf has been widely used as a reinforcement. Continuous fiber toughened ceramic matrix composites do not require higher preparation temperatures and pressures. Fibers can produce significant toughening effects, enhance material strength and toughness, and improve material thermal shock resistance. Ultra-high temperature ceramics are added to SiC and other second phases. It will also improve the material's anti-oxidation and anti-ablation properties. The above advantages make continuous fiber toughened ceramic matrix composites become a research hotspot of ultra-high temperature materials.

3 Conclusion

Ultra-high temperature ceramic matrix composites have excellent development prospects in the aerospace and weaponry fields due to their excellent comprehensive properties. At this stage, the mechanical properties, oxidation and ablation resistance, and thermal shock resistance of ultra-high temperature ceramic matrix composites And the study of microstructure and performance mechanism has fully proved its special position in high-temperature structural materials, but there are still a large number of unknown mechanisms and performances that need to be explored, and many practical application problems 3 Conclusion

Ultra-high temperature ceramic matrix composites have excellent development prospects in the aerospace and weaponry fields due to their excellent comprehensive properties. At this stage, the mechanical properties, oxidation and ablation resistance, and thermal shock resistance of ultra-high temperature ceramic matrix composites And the study of microstructure and performance mechanism has fully proved its special position in high-temperature structural materials, but there are still a large number of unknown mechanisms and performances that need to be explored, and need to overcome many practical application problems.

1 Ultra-high temperature ceramic matrix composite materials

Ultra-high temperature ceramic matrix composite materials refer to high temperature structural materials that can maintain stable physical and chemical properties in a high temperature environment of 2000 ℃ and above, and are based on ceramic phases. They have low density, wear resistance, excellent high temperature physical properties, and thermochemical stability. Outstanding advantages such as good performance and good thermal shock resistance. The minimum operating temperature of ultra-high temperature ceramic matrix composite materials should be higher than its operating temperature in the air (1600 ℃). In practical applications, the requirements for the operating temperature of ultra-high speed aircraft are higher, so 2000 ℃ has been listed as ultra-high temperature materials. Temperature limit. Commonly used materials are high melting point carbides, borides, nitrides and their composite materials. At present, the more widely studied ultra-high temperature ceramic matrix composite materials mainly include three major systems, namely carbide ceramic matrix composite materials, boride ceramic matrix composite materials and continuous fiber toughened ceramic matrix composite materials.

1.1 Carbide ceramic matrix composites

Ultra-high temperature carbide ceramics mainly include zirconium carbide (ZrC), hafnium carbide (HfC), tantalum carbide (TaC), titanium carbide (TiC), etc., with high melting point, high temperature strength, excellent electrical and thermal conductivity, and good thermal shock resistance However, due to its brittleness and insufficient oxidation resistance, silicon carbide (SiC), zirconium boride (ZrB2), zirconium oxide (ZrO2), molybdenum silicide (MoSi2), molybdenum (Mo) metal, graphite are often added (Cg) and other particles enhance its mechanical properties, improve its oxidation resistance and sintering properties. Common carbide ceramic matrix composite materials include ZrC-SiC, ZrC-ZrB2, ZrC-ZrO2, ZrC-MoSi2, ZrCMo, ZrC-SiC-Cg, HfC-SiC, TaC-SiC, TiC-SiC, etc.

1.2 Boride ceramic matrix composites

Ultra-high temperature boride ceramics mainly include zirconium boride (ZrB2), hafnium boride (HfB2), tantalum boride (TaB2) and titanium boride (TiB2). There are strong covalent bonds in ultra-high temperature boride ceramics, which have the advantages of high melting point, high strength, high thermal and electrical conductivity, and low evaporation rate. However, the strong covalent bond characteristics make it difficult to sinter and densify the material. The high temperature oxidation resistance of the material also needs to be improved.

ZrB2 and HfB2 are the most widely studied ultra-high temperature boride ceramics. By adding SiC to prepare ZrB2-SiC and HfB2-SiC composite materials, a higher binary eutectic temperature can be obtained, and the mechanical and oxidation resistance of the material can be improved. Jin et al. studied the oxidation behavior of ZrB2-SiC-Cg composites under low oxygen partial pressure, using X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), scanning electron microscope (SEM) and X-ray energy dispersion Spectroscopy (EDS) analyzes the microscopic composition of the oxidized sample. The results show that low oxygen partial pressure has a significant effect on the phase composition of the oxide layer surface and the microstructure of the oxide layer. Higher oxygen partial pressure accelerates the oxidation behavior of ZrB2-SiC-Cg composites.

1.3 Continuous fiber toughened ceramic matrix composites

Continuous fiber toughened ceramic matrix composites refer to ultra-high temperature ceramics or multiphase ceramics as the matrix, such as ZrC, ZrB2, HfC, HfB2, TaC, ZrC-SiC, ZrB2-SiC, HfB2-SiC, ZrB2-ZrC-SiC, etc. , With high temperature resistant fibers as reinforcements, such as carbon fiber (Cf), silicon carbide fiber (SiCf), etc., ultra-high temperature composite materials with high strength, high toughness, low density, high temperature resistance and other excellent properties are formed.

The high temperature resistant fiber has low density, high strength and good high temperature performance. Among them, Cf has been widely used as a reinforcement. Continuous fiber toughened ceramic matrix composites do not require higher preparation temperatures and pressures. Fibers can produce significant toughening effects, enhance material strength and toughness, and improve material thermal shock resistance. Ultra-high temperature ceramics are added to SiC and other second phases. It will also improve the material's anti-oxidation and anti-ablation properties. The above advantages make continuous fiber toughened ceramic matrix composites become a research hotspot of ultra-high temperature materials.

3 Conclusion

Ultra-high temperature ceramic matrix composites have excellent development prospects in the aerospace and weaponry fields due to their excellent comprehensive properties. At this stage, the mechanical properties, oxidation and ablation resistance, and thermal shock resistance of ultra-high temperature ceramic matrix composites And the study of microstructure and performance mechanism has fully proved its special position in high-temperature structural materials, but there are still a large number of unknown mechanisms and performances that need to be explored, and many practical application problems 3 Conclusion

Ultra-high temperature ceramic matrix composites have excellent development prospects in the aerospace and weaponry fields due to their excellent comprehensive properties. At this stage, the mechanical properties, oxidation and ablation resistance, and thermal shock resistance of ultra-high temperature ceramic matrix composites And the study of microstructure and performance mechanism has fully proved its special position in high-temperature structural materials, but there are still a large number of unknown mechanisms and performances that need to be explored, and need to overcome many practical application problems.

.png)