.png)

(1).jpg)

(1).jpg)

(1).jpg)

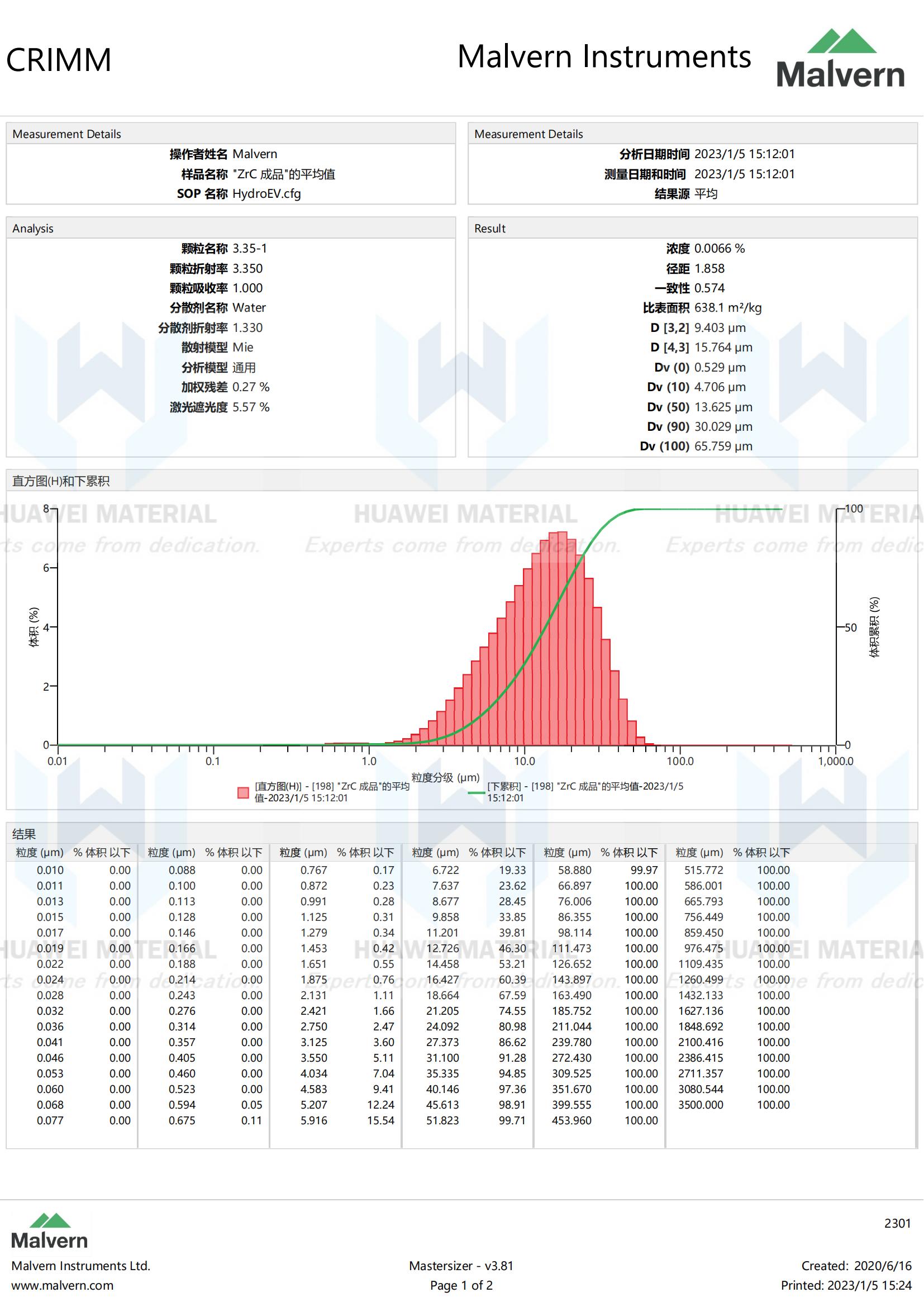

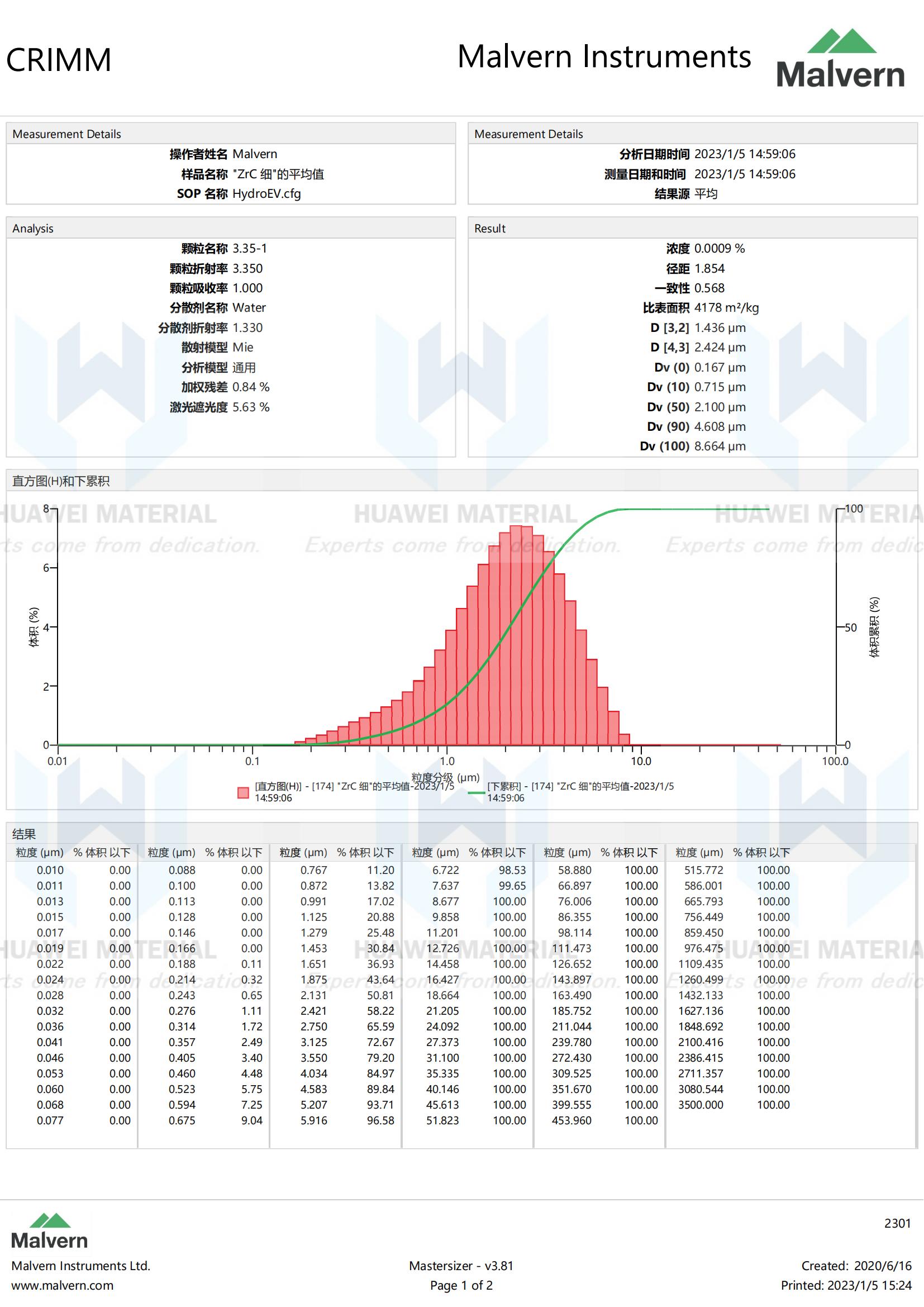

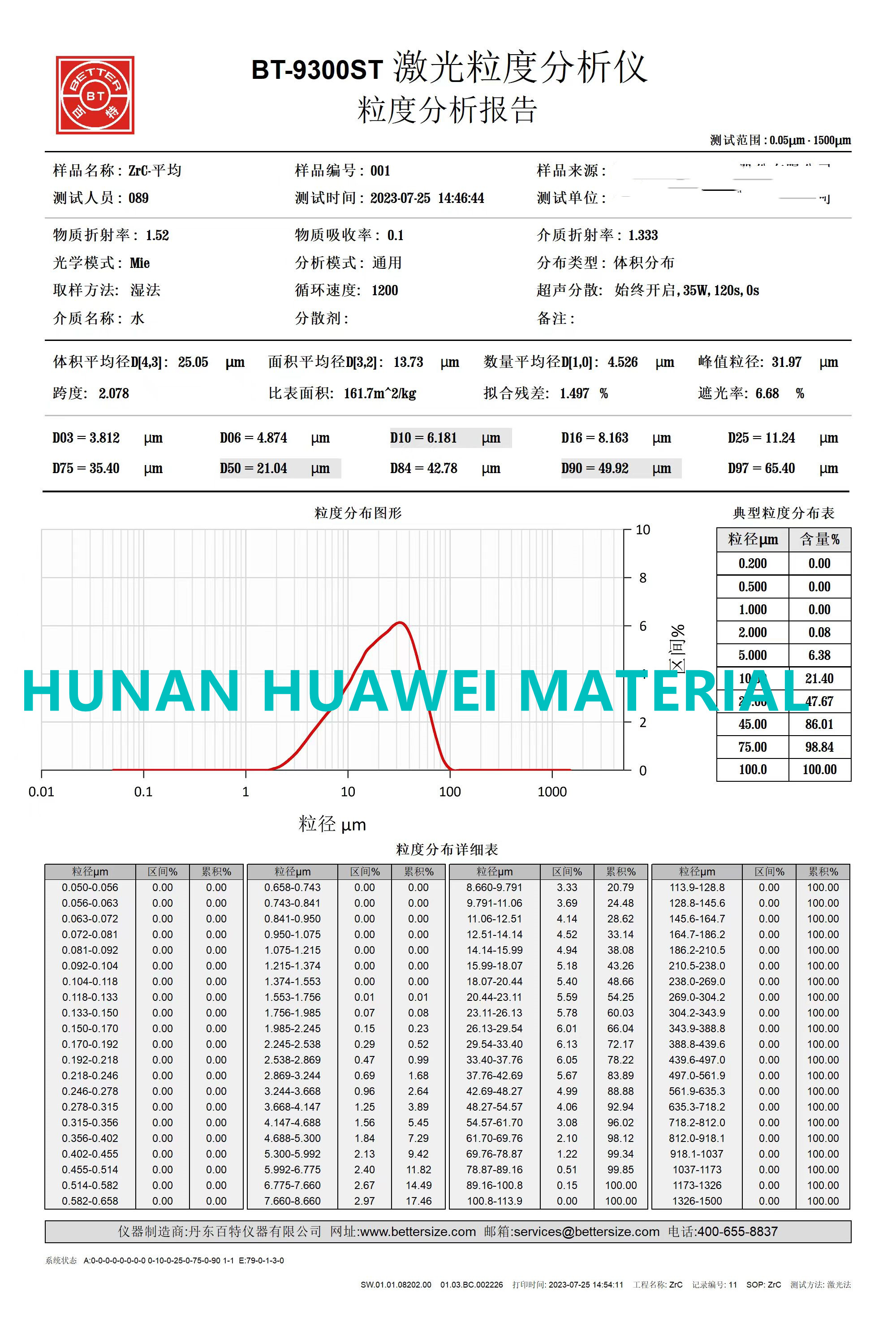

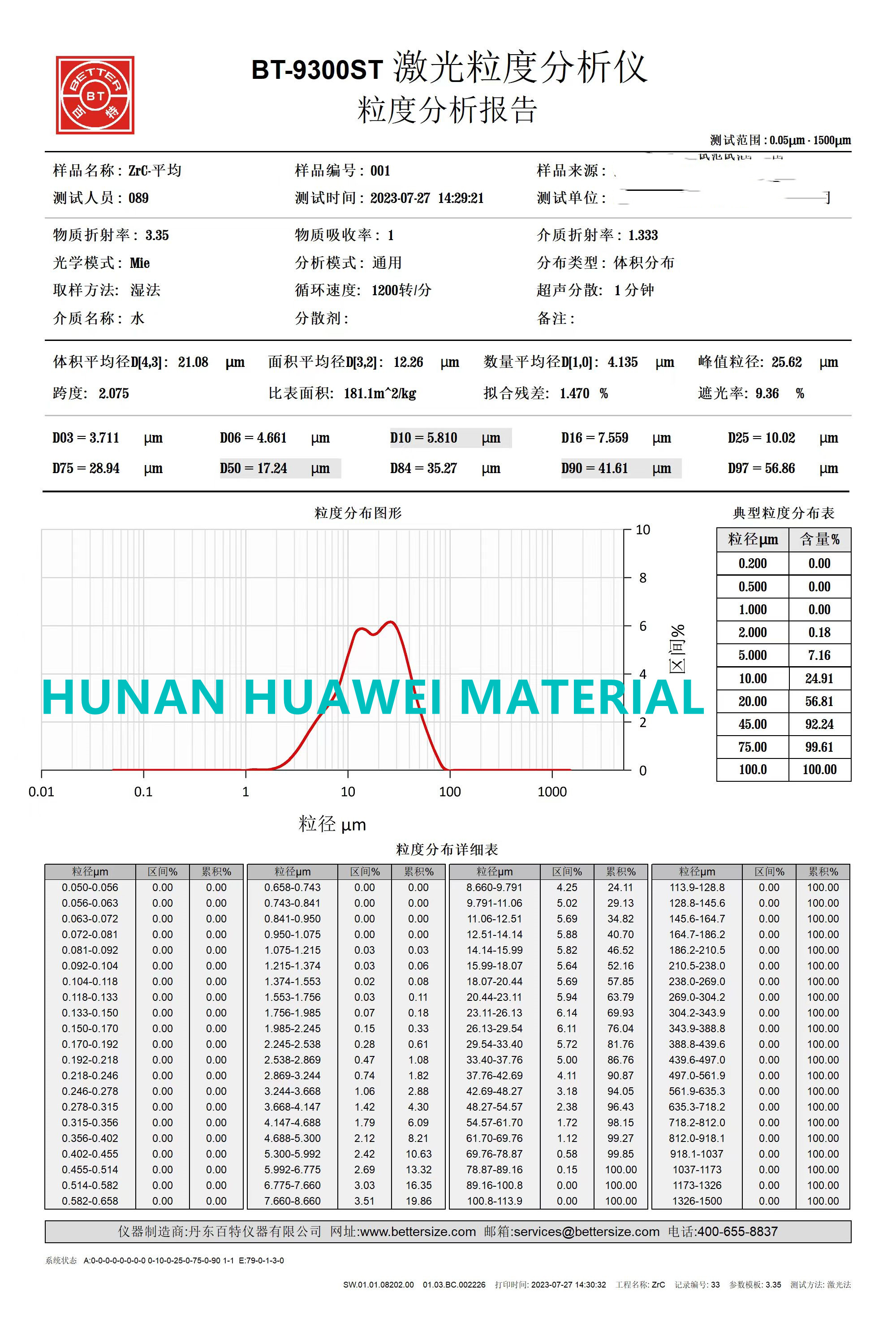

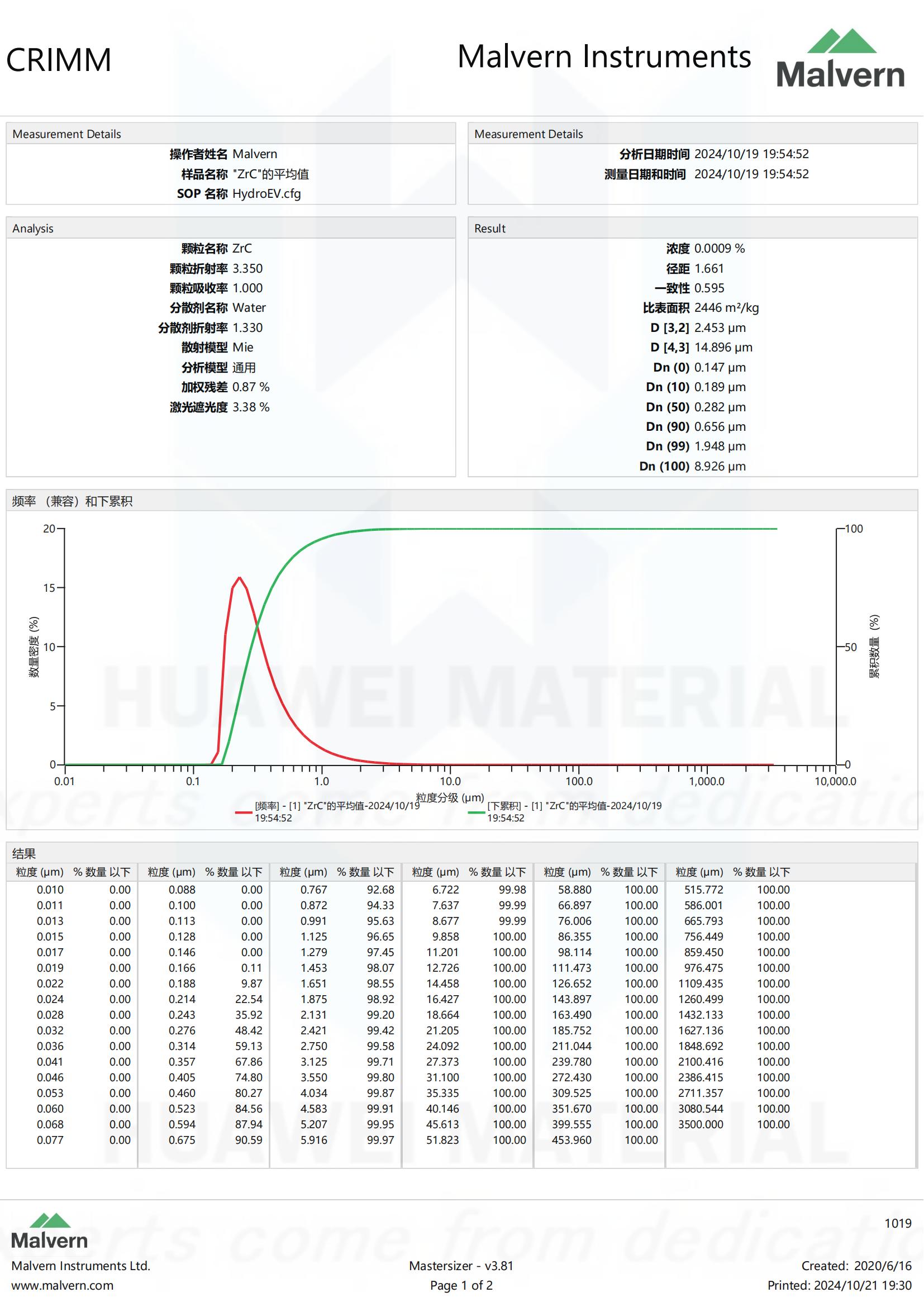

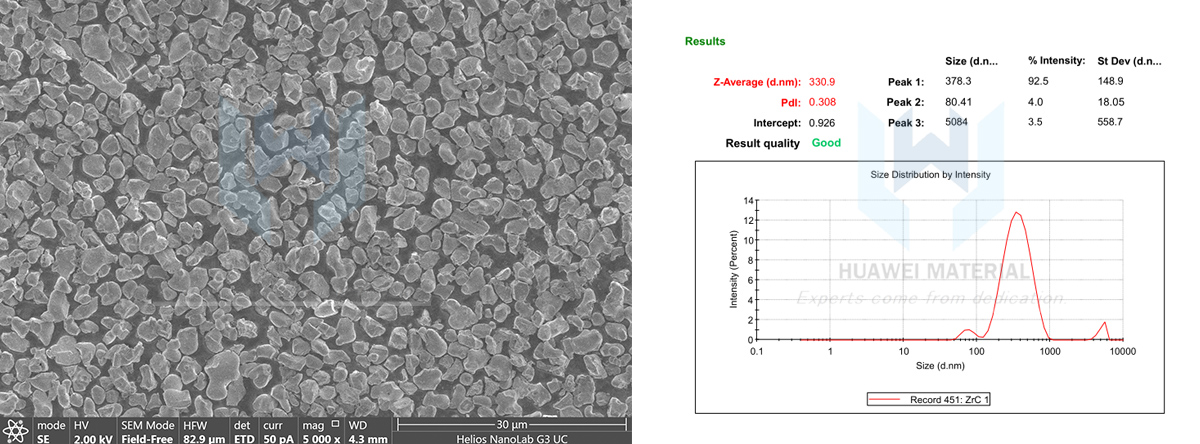

| Model | Average Particle Size (D50) | Purity(%) | O(%) | N(%) | CF(%) | CT(%) |

| ZrC3000 | 30-50nm | >99.0 | -- | -- | -- | 10.8~11.4 |

| ZrC0800 | 0.5-1.0um | >99.0 | ≤1.0 | ≤0.10 | ≤0.1 | 10.8~11.4 |

| ZrC0020 | 1.0-3.0um | >99.5 | ≤.0.8 | ≤0.10 | ≤0.1 | 10.8~11.4 |

| ZrC0021 | 1.0-3.0um (80% concentrated) |

>99.5 | ≤0.8 | ≤0.10 | ≤0.1 | 10.8~11.4 |

| ZrC0003 | 10.0-60.0um | >99.9 | ≤0.5 | ≤0.05 | ≤0.1 | 10.8~11.4 |

| ZrC0008 | -100+325mesh | >99.9 | ≤0.3 | ≤0.05 | ≤0.1 | 10.8~11.4 |

| ZrC0001 | -200mesh | >99.99 | ≤0.1 | ≤0.01 | ≤0.001 | 10.8~11.4 |

| Customized chemical composition and particle size can be made according to customer requirements. | ||||||

| Size | Average Particle Size (D50) | Size Distribution Range |

| ZrC3000 | 30-50nm | D50:30-50nm,D90<100nm |

| ZrC0800 | 0.5-1.0um | Type 1:D50<1.0um,Type 2:D90<1.0um |

| ZrC0020 ZrC0021 |

1.0-3.0um | Type 1:D50:1.0~3.0um,D90:3.5-4.5um Type 2:<1.0um≯10%,>3.0um≯10%,1.0-3.0um≥80% |

| ZrC0003 | 10.0-60.0um | <10.0um≯10%,>60.0um≯5%,10-60um≥80% |