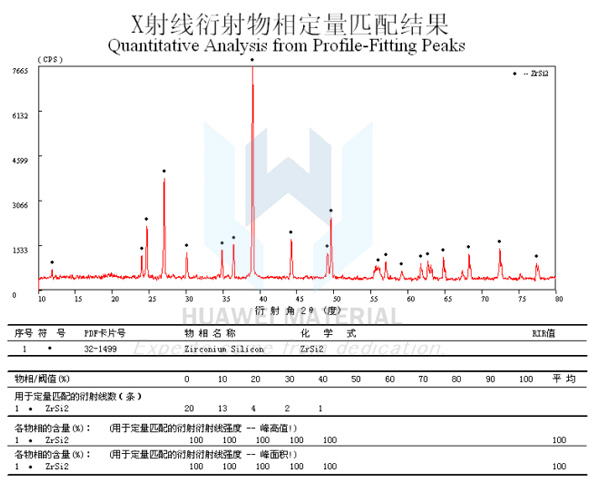

ZrSi2 is a typical insoluble metal silicide. Refractory metal silicide has a high melting point, hardness and compressive strength, high temperature creep strength, medium density and tensile strength, and good temperature mechanical properties. The reaction of metal and silicon reduces the activity of the metal, so silicidation The chemical stability of the material is quite good. The refractory metal silicides with high silicon content have good corrosion resistance and oxidation resistance at room temperature and high temperature. The physical and chemical properties of metal silicides make them have many uses. First of all, silicides as high-temperature structural materials have good application prospects in aviation, aerospace, and chemical industries. They are used as high-temperature anti-oxidation coatings and magnetic materials. Functional materials such as integrated circuit electrode films have been widely studied and applied.Ceramic matrix composite material is a new type of thermal structure/function integrated material with the advantages of metal materials, ceramic materials and carbon materials. It has high temperature resistance, low density, high specific strength, high specific mode, oxidation resistance, and ablation resistance. , It is not sensitive to cracks and does not cause catastrophic damage. It has a wide range of applications in machinery, aerospace, nuclear, energy and other fields. The in-situ synthesis of refractory metal carbides (ZrC, HfC, TaC) in C/SiC composite materials can significantly improve its anti-ablation performance. The main mechanism can be summarized as inhibiting oxidation, enhancing the matrix anti-erosion performance and making up for the ablation Defects, ZrSi2 can be used as a source of Zr for in-situ synthesis of ZrC.