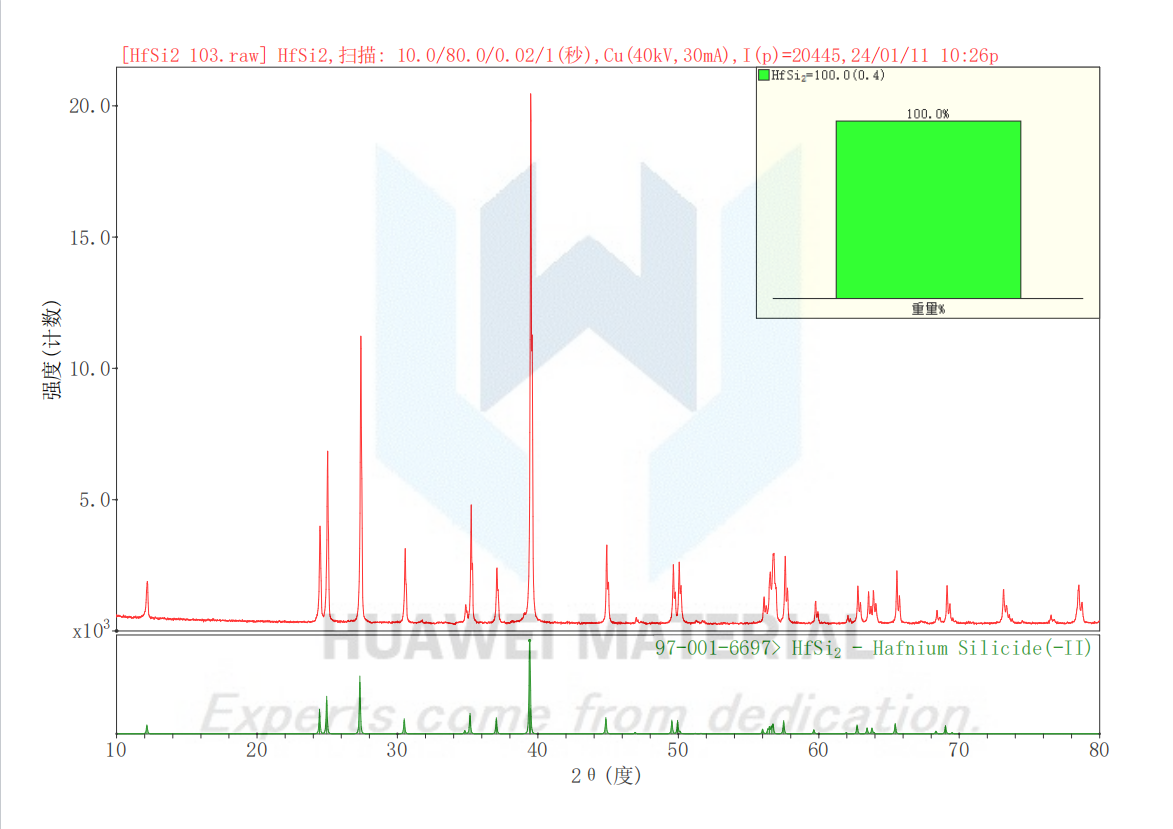

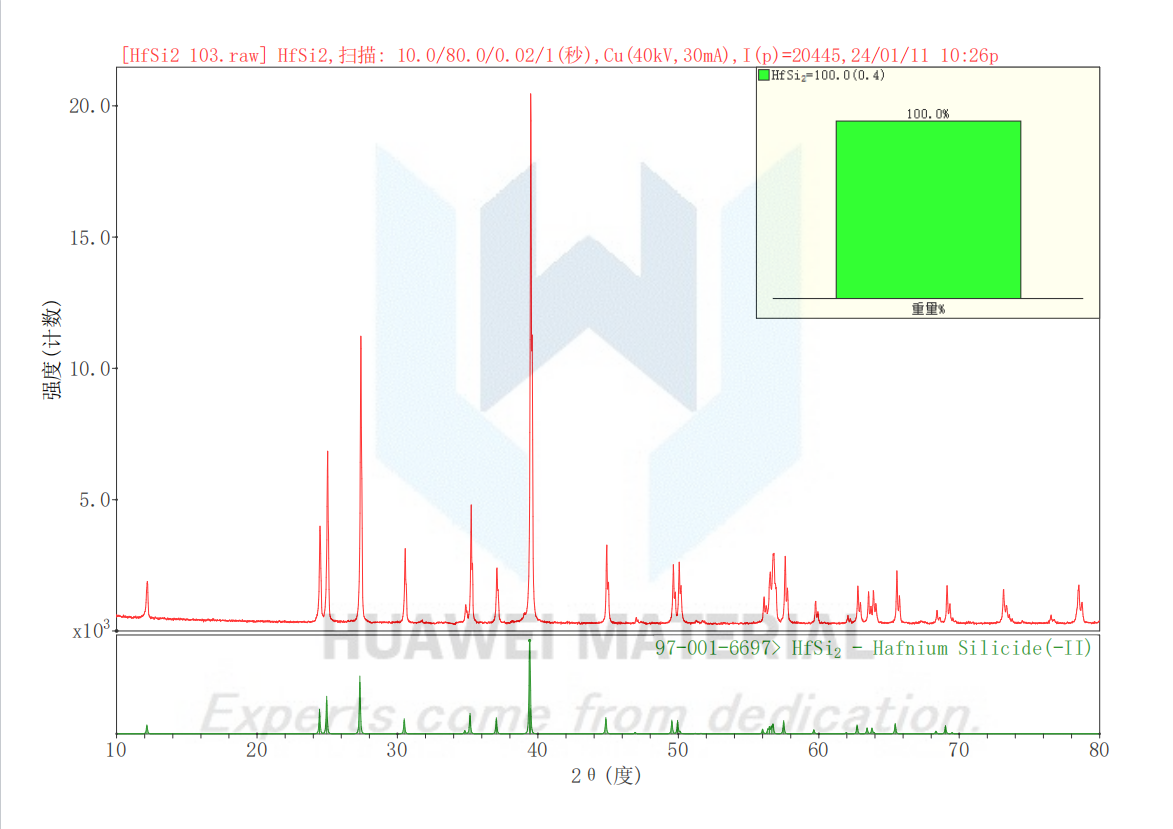

Hafnium disilicide (HfSi2) is a transition metal silicide, a type of refractory intermetallic compound. Because of its unique physical and chemical properties, it is used in cermets, high-temperature oxidation-resistant coatings, high-temperature structural materials and aviation , Aerospace and other fields.

Ceramic matrix composite material (C/C, C ceramic) is a new type of thermal structure/function integrated material that combines the performance advantages of metal materials, ceramic materials and carbon materials. It has high temperature resistance, low density, high specific strength and high specificity. It has the characteristics of mold, oxidation resistance, ablation resistance, insensitivity to cracks, and no catastrophic damage. It has a wide range of applications in machinery, aerospace, nuclear, energy and other fields.

C/C composite materials can be used as thermal structural materials for gas turbine engine structural components, space shuttle nose cone caps, wing leading edges, etc. Most of these components work in high temperature and oxidation environments. However, C/C composite materials are easy to oxidize and usually cannot be serviced in an oxidizing atmosphere higher than 400 ℃. This requires proper oxidation protection for C/C composite materials. In-situ synthesis of refractory metal carbides (HfC, HfC, TaC) in C/SiC composite materials can significantly improve its ablation resistance. The main mechanism can be summarized. In order to inhibit oxidation, enhance the erosion resistance of the matrix and make up for the defects after ablation, HfSi2 can be used as an Hf source for in-situ synthesis of HfC.

.png)

.png)