Ultra-high temperature ceramics

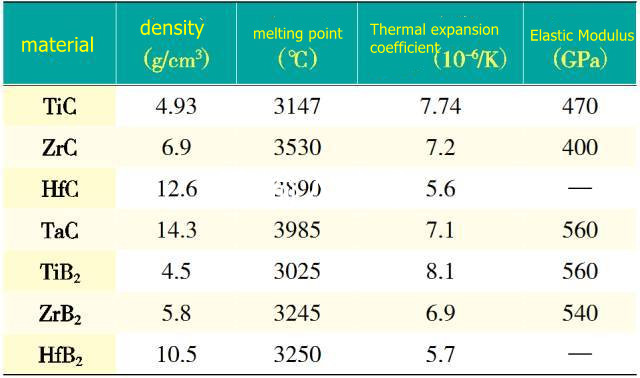

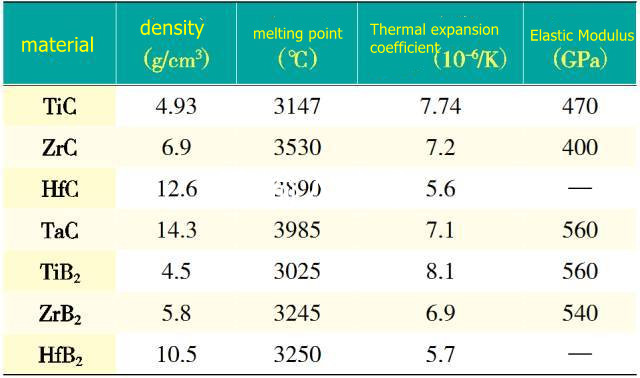

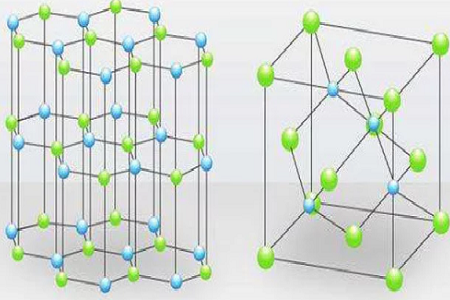

Ultra-high temperature ceramics refers to a special material that can maintain physical and chemical stability in a high temperature environment (2000 ℃) and a reactive atmosphere (such as in an atomic oxygen environment). It has excellent high temperature mechanical properties, high temperature oxidation resistance. and thermal shock resistant ceramic matrix composites. Ultra-high temperature ceramics are mainly composed of high melting point borides and carbides, mainly including hafnium boride (HfB2), zirconium boride (ZrB2), hafnium carbide (HfC), zirconium carbide (ZrC), tantalum carbide (TaC), etc. The melting point of boride and carbide ultra-high temperature ceramics is over 3000 ℃, with excellent thermochemical stability and excellent physical properties, including high elastic modulus, high hardness, low saturated vapor pressure, moderate thermal expansion rate and good heat resistance shock performance, etc., and can maintain high strength at high temperatures. Ultra-high temperature ceramics can adapt to extreme environments such as hypersonic long-term flight, atmospheric reentry, transatmospheric flight and rocket propulsion systems, and can be used in various key components such as aircraft nose cones, wing leading edges, and engine hot ends. As an important material used in aerospace vehicles, ultra-high temperature ceramic materials have received great attention from various countries. Table 2 is the thermophysical properties of common ultra-high temperature ceramics.

related news

-

Oct 20, 2022Evaluation of the durability of ZrC as support material for Pt electrocatalysts in PEMFCs

Oct 20, 2022Evaluation of the durability of ZrC as support material for Pt electrocatalysts in PEMFCs -

Apr 07, 2023Preparation and Properties of HfC Ceramic Precursor

Apr 07, 2023Preparation and Properties of HfC Ceramic Precursor -

Jan 04, 2022Application of carbide ceramic materials in the field of nuclear reactors

Jan 04, 2022Application of carbide ceramic materials in the field of nuclear reactors -

Nov 22, 2021Preparation and Application of Boron Nitride (BN) Materials

Nov 22, 2021Preparation and Application of Boron Nitride (BN) Materials