Introduction to Thermal Spray

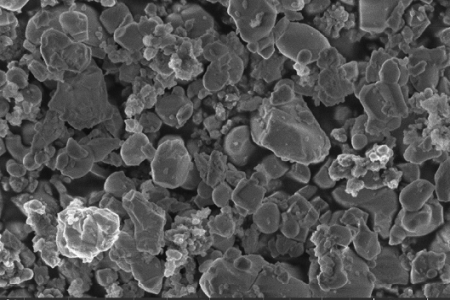

1. Thermal spraying (hafnium carbide, zirconium carbide, titanium carbide, molybdenum disilicide, hafnium diboride) is a surface strengthening technology, an important part of surface engineering technology, and has always been a new technology project promoted by my country. It is to use a certain heat source (such as arc, plasma spraying or combustion flame, etc.) to heat powder or filamentary metal or non-metallic materials to a molten or semi-molten state, and then use the flame itself or compressed air to spray it at a certain speed. A technique for depositing a treated substrate surface to form a surface coating with various functions.

2. Principle of thermal spraying: Thermal spraying refers to a series of processes in which fine and dispersed metallic or non-metallic coating materials are deposited on the surface of a prepared substrate in a molten or semi-molten state. , forming some kind of spray deposition layer. The coating material can be in the form of powder, ribbon, wire or rod. The thermal spray gun provides the necessary heat by fuel gas, electric arc or plasma arc, heats the thermal spray material to a plastic or molten state, and then is accelerated by compressed air, so that the confined particle beam impinges on the surface of the substrate. The particles impacting the surface are deformed by stamping to form a laminated sheet, which adheres to the surface of the prepared substrate, then cools and accumulates continuously, eventually forming a layered coating. The coating can achieve high temperature corrosion resistance, wear resistance, heat insulation, electromagnetic wave resistance and other functions due to different coating materials.

Through continuous process improvement and technological innovation, the company has achieved a qualitative leap in product quality. Experimental data and customer use show that our product quality has reached the world's advanced level. At the same time, in order to meet the growing needs of customers and improve the company's product structure, the company has continuously increased investment in equipment and product research and development, and has produced a series of spherical metal composite powder products, including hafnium carbide, zirconium carbide, titanium carbide , molybdenum disilicide, hafnium diboride and other products, and can be customized according to customer's technical requirements.

morphology powder particle size fluidity value

1 spherical Zrc 10-60um 17.44s/50g

2 spherical TaC 10-60um 8.91s/50g

3 spherical Hf 15-53um 11.78s/50g

4 spherical TaNbMo 10-60um 9.57s/50g

5 spherical TaNbMo 60-100um 9.11s/50g

6 spherical HfC 10-60um 9.95s/50g

2. Principle of thermal spraying: Thermal spraying refers to a series of processes in which fine and dispersed metallic or non-metallic coating materials are deposited on the surface of a prepared substrate in a molten or semi-molten state. , forming some kind of spray deposition layer. The coating material can be in the form of powder, ribbon, wire or rod. The thermal spray gun provides the necessary heat by fuel gas, electric arc or plasma arc, heats the thermal spray material to a plastic or molten state, and then is accelerated by compressed air, so that the confined particle beam impinges on the surface of the substrate. The particles impacting the surface are deformed by stamping to form a laminated sheet, which adheres to the surface of the prepared substrate, then cools and accumulates continuously, eventually forming a layered coating. The coating can achieve high temperature corrosion resistance, wear resistance, heat insulation, electromagnetic wave resistance and other functions due to different coating materials.

Through continuous process improvement and technological innovation, the company has achieved a qualitative leap in product quality. Experimental data and customer use show that our product quality has reached the world's advanced level. At the same time, in order to meet the growing needs of customers and improve the company's product structure, the company has continuously increased investment in equipment and product research and development, and has produced a series of spherical metal composite powder products, including hafnium carbide, zirconium carbide, titanium carbide , molybdenum disilicide, hafnium diboride and other products, and can be customized according to customer's technical requirements.

morphology powder particle size fluidity value

1 spherical Zrc 10-60um 17.44s/50g

2 spherical TaC 10-60um 8.91s/50g

3 spherical Hf 15-53um 11.78s/50g

4 spherical TaNbMo 10-60um 9.57s/50g

5 spherical TaNbMo 60-100um 9.11s/50g

6 spherical HfC 10-60um 9.95s/50g

related news

.png)