Ultra-high temperature ceramics ZrB2 and HfB2

Modern aircraft such as spacecraft, artificial satellites, rockets, missiles, supersonic aircraft are toward high speed, high altitude, large thrust, long distance, high accuracy and more safe direction development, development, the demand for ultra-high temperature materials is more and more urgent. Especially the new generation space, near space flight path is by leaps and bounds, the jumping track low combustion engine ignition work, open the rest of the time on higher resistance than the aerodynamic shape gliding, aircraft nose cone and wing leading edge need to be higher than 2000 ℃ the neutral or oxidation conditions, the structural material of high temperature strength, oxidation resistance and thermal shock resistance is put forward New requirements. At present, there are mainly two kinds of materials that meet the application conditions: one is ultra-high temperature ceramic material (UHTCs), the other is carbon fiber composite material (especially, with SiC as matrix, the former has quite high temperature oxidation resistance, but the density is too large; Because of its excellent surface thermo-mechanical properties and low density, the latter has become a practical material in the future, but it needs the protection of anti-oxidation layer in application. In ultra-high temperature ceramics In ceramics(UHTCs), ZrB2 and HfB2 are the most attractive thermal protective materials, especially HfB2 with a series of unique excellent properties: high melting point (3250℃), high hardness (29GPa), high conductivity (15 Ω•cm) and high chemical stability. The combination of these properties makes it a potential high-temperature structural material with a wide range of applications, including engines, supersonic aircraft, plasma discharges, cutting tools, furnace components, etc. HfB2, in particular, has a very low oxidation rate and can be used as a thermal protection system for space vehicles.

.png)

.png)

related news

-

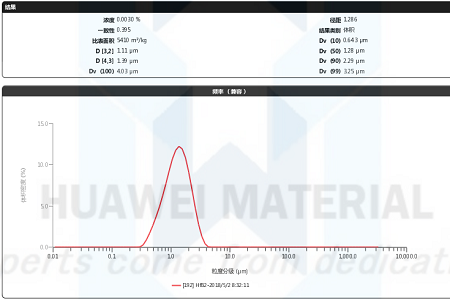

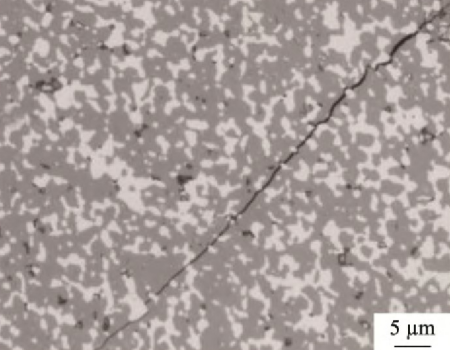

Dec 23, 2021Investigation on Synthesis of Hafnium Diboride Powder by Reductive Reaction

Dec 23, 2021Investigation on Synthesis of Hafnium Diboride Powder by Reductive Reaction -

Feb 28, 2022Research on ultra-high temperature ceramic materials(1)

Feb 28, 2022Research on ultra-high temperature ceramic materials(1) -

Feb 18, 2022Research progress of B4C-TiB2 composite ceramic materials(2)

Feb 18, 2022Research progress of B4C-TiB2 composite ceramic materials(2) -

.png) May 23, 2022Carbide ultra-high temperature ceramics have high melting point, high strength, high hardness and good chemical stability, and are widely used ultra-high temperature ceramic materials

May 23, 2022Carbide ultra-high temperature ceramics have high melting point, high strength, high hardness and good chemical stability, and are widely used ultra-high temperature ceramic materials