Research on ultra-high temperature ceramic materials(1)

Ultra-high temperature ceramics refer to ceramic matrix composites that can be used above 1800 °C and have excellent high temperature oxidation resistance and thermal shock resistance. Ultra-high temperature ceramics can adapt to extreme environments such as hypersonic long-term flight, atmospheric reentry, transatmospheric flight and rocket propulsion systems, and can be used in various key parts or components such as aircraft nose cones, wing leading edges, and engine hot ends.

Among the high melting point compounds, carbides have the highest melting point, followed by borides. Ultra-high temperature ceramics are mainly composed of high melting point borides and carbides. Among them, HfB2, ZrB2, HfC, ZrC, TaC and other borides and carbide ultra-high temperature ceramics have melting points over 3000 °C, no phase change, and excellent thermochemical stability, and excellent physical properties, including high elastic modulus, high hardness, low saturated vapor pressure, high thermal conductivity and electrical conductivity, moderate thermal expansion rate and good thermal shock resistance, etc., and can maintain high strength at high temperatures . They become the most potential candidate material for ultra-high temperature ceramics.

Boride Ceramic Matrix Composites

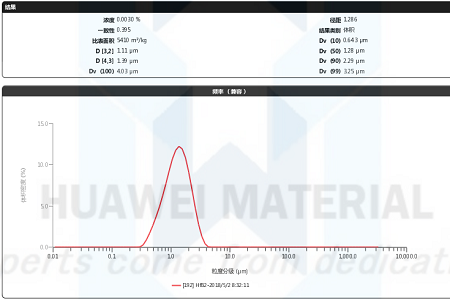

Studies have shown that the brittleness and low room temperature strength of ZrB2 and HfB2 based ceramic composites can be overcome by rational selection of the composition, purity and particle size of the raw materials, and their strong covalent bonds determine that they are difficult to sinter and densify. ZrB2-SiC material has high strength (over 1000MPa) and oxidation resistance, this material can rise from room temperature to 2200℃ in less than 30s without being damaged, showing good thermal shock resistance.

Hafnium carbide (HfC), zirconium carbide (ZrC) and tantalum carbide (TaC) have higher melting points than their borides, do not undergo any solid phase transformation, have good thermal shock resistance, and still have high strength at high temperatures . The fracture toughness and oxidation resistance of such carbide ceramics are very low. In order to overcome the brittleness of ceramics, fibers are usually used to strengthen and toughen them.

Among the high melting point compounds, carbides have the highest melting point, followed by borides. Ultra-high temperature ceramics are mainly composed of high melting point borides and carbides. Among them, HfB2, ZrB2, HfC, ZrC, TaC and other borides and carbide ultra-high temperature ceramics have melting points over 3000 °C, no phase change, and excellent thermochemical stability, and excellent physical properties, including high elastic modulus, high hardness, low saturated vapor pressure, high thermal conductivity and electrical conductivity, moderate thermal expansion rate and good thermal shock resistance, etc., and can maintain high strength at high temperatures . They become the most potential candidate material for ultra-high temperature ceramics.

Boride Ceramic Matrix Composites

Studies have shown that the brittleness and low room temperature strength of ZrB2 and HfB2 based ceramic composites can be overcome by rational selection of the composition, purity and particle size of the raw materials, and their strong covalent bonds determine that they are difficult to sinter and densify. ZrB2-SiC material has high strength (over 1000MPa) and oxidation resistance, this material can rise from room temperature to 2200℃ in less than 30s without being damaged, showing good thermal shock resistance.

Hafnium carbide (HfC), zirconium carbide (ZrC) and tantalum carbide (TaC) have higher melting points than their borides, do not undergo any solid phase transformation, have good thermal shock resistance, and still have high strength at high temperatures . The fracture toughness and oxidation resistance of such carbide ceramics are very low. In order to overcome the brittleness of ceramics, fibers are usually used to strengthen and toughen them.

related news

-

Mar 09, 2022Lanthanum hexaboride properties and application

Mar 09, 2022Lanthanum hexaboride properties and application -

Dec 23, 2021Investigation on Synthesis of Hafnium Diboride Powder by Reductive Reaction

Dec 23, 2021Investigation on Synthesis of Hafnium Diboride Powder by Reductive Reaction -

.png) Nov 02, 2021Do you know what material can be made of cermet?Talking about the five advantages of cermet

Nov 02, 2021Do you know what material can be made of cermet?Talking about the five advantages of cermet -

Nov 24, 2021Introduction to the application of titanium carbide (TiC)

Nov 24, 2021Introduction to the application of titanium carbide (TiC)