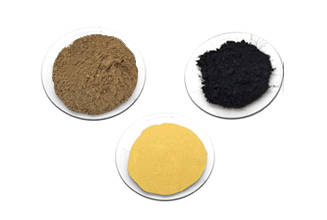

application of zirconium carbide powder

ZrC is one of the potential materials for high temperature applications in hypersonic vehicles and weapons points like re-entry vehicle, rocket/Scram jet engine or supersonic vehicle, several industrial sectors, such as foundry, nuclear power plants, cutting tools or metallurgical industries. ZrC has a face centered cubic structure (rocksalt crystal structure) having Fm3m space group and lattice parameter is 4.6796A. Carbon is occupying the the octahedral interstitial sites and a wide homogeneity region exists for the monocarbons. The complete stoichiometry is rarely formed in ZrC phase and the ratio of C to Zr can be varied from 0.3 to 0.98. It has potentially tailorable thermomechanical and thermophysical properties due to the large substoichiometric phase stability field associated with vacancies in the C sublattice. Zirconium carbide (ZrC) ceramics have a high melting point(~3530C) due to strong covalent bonding of Zr-C (Enthalpyof formation -197 kJ.mol-1); high hardness (~25GPa), high electrical conductivity (resistivity ~ 40Ω.cm) due to presence of metallic Zr-Zr bond; high load bearing capabilities, excellent corrosion resistance against molten iron and slags, super ther- mal shock resistance. It has lower density (6.73 g/cm3) compared to other ultra high temperature ceramics (UHTC) based on carbides like WC, TiC,HfC etc.

.jpg)

(1).jpg)