Strengthening and Toughening of Zirconium Diboride Ultra-High Temperature Ceramics

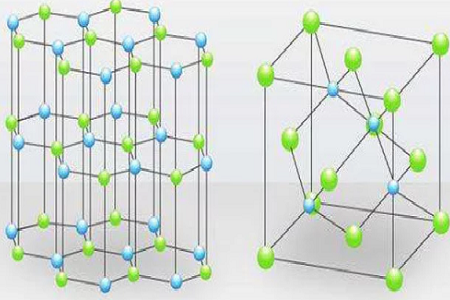

Zirconium diboride (ZrB2) is a typical ultra-high temperature ceramic material, with high melting point (3 245 ℃), high strength, high hardness, and excellent electrical conductivity, thermal conductivity, corrosion resistance, and ion trapping properties. It is used in aerospace , Electronics, nuclear industry and other fields have been widely developed and applied, especially in hypersonic aircraft as a heat-proof material, has a good application prospects. However, in addition to the high sintering temperature and poor oxidation and ablation resistance at high temperatures, the low fracture toughness also severely limits its wide application in harsh environments such as high temperatures. Therefore, the strengthening and toughening of ZrB2 ceramics has become a research hotspot in recent years.

The research on the strengthening and toughening of ceramic materials has a long history. The commonly used strengthening and toughening methods are mainly: adding toughening phases (such as fibers, whiskers, particles, zirconia phase transformation toughening), bionic structural toughening (such as fiber alone Stone structure, layered structure, etc.). The essence of toughening is to introduce a mechanism for absorbing fracture energy in the material, through crack deflection, fiber (or whisker) bridging, fiber (or whisker) pull-out, phase change toughening, micro-crack toughening, and weak interface layer Toughening mechanisms such as repeated deflection of cracks can improve the fracture toughness of ceramic materials. For the research on the strengthening and toughening of zirconium diboride ceramic materials, people have also carried out a lot of work. Carbon fibers, silicon carbide particles, whiskers or wafers are also often used as toughening phases, which can improve the performance of ZrB2 ceramics to a certain extent. Fracture toughness. However, there is still a lack of systematic research on the strengthening and toughening of zirconium diboride ceramics, and its mechanical properties still have much room for improvement.

Using silicon carbide particles, whiskers, and wafers as toughening phases, SiC/ZrB2 ceramic matrix composites were prepared by hot-press sintering. The morphology and content of different toughening phases on the strengthening and toughening effects of zirconium diboride ceramics were studied. Through the design of the layered structure and the spark plasma sintering technology, the layered ZrB2 ceramic matrix composite was prepared, and the toughening effect of the layered structure on the zirconium diboride ceramic was discussed.

Conclusion

1 By adding SiC particles, whiskers or wafers, hot-press sintering can be used to prepare nearly completely dense SiC/ZrB2 ceramic matrix composites. The addition of SiC phase promotes sintering densification, while inhibiting the growth of ZrB2 matrix grains Therefore, it is beneficial to improve the mechanical properties of ZrB2 ceramic matrix composites.

2 Compared with ZrB2 ceramic matrix composites with SiC particles or whiskers added separately, the toughening effect of adding SiC particles and whiskers at the same time is more obvious. The best addition amount is 10%SiCp + 10%SiCw, at this time the strength It can reach 620 MPa, and the fracture toughness can reach 9.0 MPa·m1/2. The high toughness is mainly derived from the bridging and pull-out mechanism of SiC whiskers, the pinning mechanism of SiC particles to cracks, and the crack deflection mechanism caused by SiC particles and whiskers, etc., reflecting a certain synergistic toughening effect.

3 SiC wafers can have a better strengthening and toughening effect. When the addition of SiC wafers is 5%, the bending strength reaches the maximum 625 MPa; when the addition of SiC wafers is 15%, the fracture toughness reaches the maximum 8.4 MPa·m1/2. However, the strengthening and toughening effect of SiC wafers is also related to its aspect ratio and size. Excessive SiC wafer size seriously hinders the sintering and densification of ZrB2 ceramics, thus weakening its strengthening and toughening effect.

4 Through the layered structure design, the fracture toughness of ZrB2 ceramics can be greatly improved. When 30% ZrB2 is added to the interface layer, the fracture toughness of ZrB2/SiC+30%ZrB2 layered ceramic composites can reach 12.3 MPa· m1/2, showing a good toughening effect, but because the size of the defects brought by the weak interface layer is larger, the strength of the ceramic is reduced to a certain extent.

The research on the strengthening and toughening of ceramic materials has a long history. The commonly used strengthening and toughening methods are mainly: adding toughening phases (such as fibers, whiskers, particles, zirconia phase transformation toughening), bionic structural toughening (such as fiber alone Stone structure, layered structure, etc.). The essence of toughening is to introduce a mechanism for absorbing fracture energy in the material, through crack deflection, fiber (or whisker) bridging, fiber (or whisker) pull-out, phase change toughening, micro-crack toughening, and weak interface layer Toughening mechanisms such as repeated deflection of cracks can improve the fracture toughness of ceramic materials. For the research on the strengthening and toughening of zirconium diboride ceramic materials, people have also carried out a lot of work. Carbon fibers, silicon carbide particles, whiskers or wafers are also often used as toughening phases, which can improve the performance of ZrB2 ceramics to a certain extent. Fracture toughness. However, there is still a lack of systematic research on the strengthening and toughening of zirconium diboride ceramics, and its mechanical properties still have much room for improvement.

Using silicon carbide particles, whiskers, and wafers as toughening phases, SiC/ZrB2 ceramic matrix composites were prepared by hot-press sintering. The morphology and content of different toughening phases on the strengthening and toughening effects of zirconium diboride ceramics were studied. Through the design of the layered structure and the spark plasma sintering technology, the layered ZrB2 ceramic matrix composite was prepared, and the toughening effect of the layered structure on the zirconium diboride ceramic was discussed.

Conclusion

1 By adding SiC particles, whiskers or wafers, hot-press sintering can be used to prepare nearly completely dense SiC/ZrB2 ceramic matrix composites. The addition of SiC phase promotes sintering densification, while inhibiting the growth of ZrB2 matrix grains Therefore, it is beneficial to improve the mechanical properties of ZrB2 ceramic matrix composites.

2 Compared with ZrB2 ceramic matrix composites with SiC particles or whiskers added separately, the toughening effect of adding SiC particles and whiskers at the same time is more obvious. The best addition amount is 10%SiCp + 10%SiCw, at this time the strength It can reach 620 MPa, and the fracture toughness can reach 9.0 MPa·m1/2. The high toughness is mainly derived from the bridging and pull-out mechanism of SiC whiskers, the pinning mechanism of SiC particles to cracks, and the crack deflection mechanism caused by SiC particles and whiskers, etc., reflecting a certain synergistic toughening effect.

3 SiC wafers can have a better strengthening and toughening effect. When the addition of SiC wafers is 5%, the bending strength reaches the maximum 625 MPa; when the addition of SiC wafers is 15%, the fracture toughness reaches the maximum 8.4 MPa·m1/2. However, the strengthening and toughening effect of SiC wafers is also related to its aspect ratio and size. Excessive SiC wafer size seriously hinders the sintering and densification of ZrB2 ceramics, thus weakening its strengthening and toughening effect.

4 Through the layered structure design, the fracture toughness of ZrB2 ceramics can be greatly improved. When 30% ZrB2 is added to the interface layer, the fracture toughness of ZrB2/SiC+30%ZrB2 layered ceramic composites can reach 12.3 MPa· m1/2, showing a good toughening effect, but because the size of the defects brought by the weak interface layer is larger, the strength of the ceramic is reduced to a certain extent.

related news

-

.jpg) Jul 07, 2022Nano titanium dioxide

Jul 07, 2022Nano titanium dioxide -

Oct 28, 2022Carbide ultra-high temperature ceramics mainly include zirconium carbide (ZrC), tantalum carbide (TaC) and hafnium carbide (HfC),

Oct 28, 2022Carbide ultra-high temperature ceramics mainly include zirconium carbide (ZrC), tantalum carbide (TaC) and hafnium carbide (HfC), -

.png) May 26, 2022ZrB2-SiC composites prepared by adding silicon carbide (SiC)

May 26, 2022ZrB2-SiC composites prepared by adding silicon carbide (SiC) -

Nov 22, 2021Preparation and Application of Boron Nitride (BN) Materials

Nov 22, 2021Preparation and Application of Boron Nitride (BN) Materials