ZrB2-SiC composites prepared by adding silicon carbide (SiC)

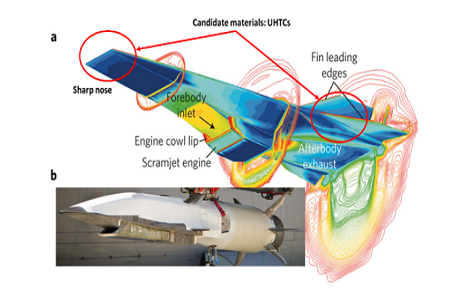

ZrB2-SiC composites prepared by adding silicon carbide (SiC) have better comprehensive properties, such as higher binary eutectic temperature and good oxidation resistance. Clougherty et al. introduced silicon carbide (SiC) into zirconium boride (ZrB2) and hafnium boride (HfB2) in the 1960s, with the initial purpose of refining grains and improving strength. After adding silicon carbide (SiC), the outermost layer of the boride surface at high temperature is mainly composed of a glass layer rich in silicon dioxide (SiO2), and the inner layer is an oxide (ZrO2, HfO2) layer. The glass layer can prevent the diffusion of oxygen, so zirconium boride (ZrB2) still has high oxidation resistance at 2000 °C after adding 20 to 30 % of silicon carbide (SiC) by volume . Sun et al. studied the effect of zirconia (ZrO2) fiber toughening on ZrB2-SiC composites. The elastic strength and fracture toughness of ZrB2-SiC-ZrO2f ceramics prepared by hot pressing method at 1850 ℃ were 1086 ± 79 MPa and 6.9 ± 0.4 MPa m1/2. At high temperature, the surface layer of ZrB2-SiC composite will form a borosilicate protective layer, which can maintain its parabolic oxidation law to more than 1600 ℃. Other additives, such as molybdenum silicide (MoSi2), zirconium silicide (ZrSi2), tantalum silicide (TaSi2), tantalum boride (TaB2), etc., are also used to improve zirconium boride (ZrB2) and hafnium boride (HfB2). ) antioxidant properties. The addition of the second phase makes the surface layer of the material at high temperature form a high-melting glass phase, which prevents the diffusion of oxygen into the material and improves the high-temperature oxidation resistance of the material.

2020_12_17_00.jpg)

2020_12_17_00.jpg)

related news

-

(1).jpg) Dec 21, 2021Strengthening and Toughening of Zirconium Diboride Ultra-High Temperature Ceramics

Dec 21, 2021Strengthening and Toughening of Zirconium Diboride Ultra-High Temperature Ceramics -

Oct 20, 2022Evaluation of the durability of ZrC as support material for Pt electrocatalysts in PEMFCs

Oct 20, 2022Evaluation of the durability of ZrC as support material for Pt electrocatalysts in PEMFCs -

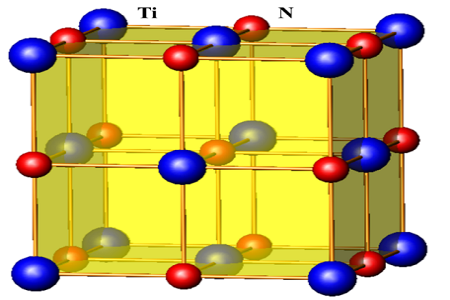

Nov 09, 2021Preparation of titanium nitride(TiN)

Nov 09, 2021Preparation of titanium nitride(TiN) -

Oct 25, 2021Comparison of different sintering methods of ZrC (zirconium carbide) ceramics and analysis of their application performance

Oct 25, 2021Comparison of different sintering methods of ZrC (zirconium carbide) ceramics and analysis of their application performance