Laser Cladding Metal-Based Titanium Carbide Strengthening Coating

Titanium carbide has excellent physical and chemical properties such as low density, high strength, high elastic modulus, oxidation resistance, wear resistance and corrosion resistance, which makes titanium carbide an ideal reinforcing material. At the same time, titanium resources are abundant, easy to obtain, and cheap, so titanium carbide has been widely used in metal matrix composites. The method of laser cladding is used to prepare metal-based titanium carbide ceramic coatings on metal surfaces, which saves materials, has simple process, low cost, high coating hardness, and greatly improves oxidation resistance and wear resistance. Therefore, laser cladding metal Titanium carbide based ceramic coating has very good application value.

Application prospect and research direction of laser cladding metal-based titanium carbide

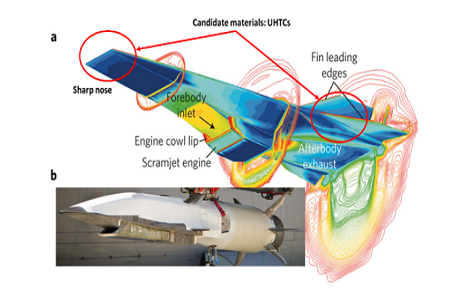

Compared with other reinforcing phases, TiC has higher hardness and thermal stability, small thermal expansion coefficient, better toughness, and better wettability of nickel-based, especially titanium-based, and is widely used as laser cladding coating. The strengthening phase in . Titanium alloys and aluminum alloys have the advantages of high specific strength, good corrosion resistance and biocompatibility, and are widely used in aerospace, national defense, automotive, medical and other fields, but titanium alloys have high temperature oxidation resistance, thermal conductivity and The poor wear resistance greatly limits the application of titanium alloys in engineering. Cladding on the surface of alloys with better mechanical properties

The metal-based titanium carbide ceramic coating with high layer hardness, excellent oxidation resistance and wear resistance can greatly increase the application range of the alloy. Due to the high melting point of TiC, incomplete melting is prone to occur, and the incompletely melted powder is easy to adhere to the surface of the cladding layer and cause the surface to become rough. In the process of laser cladding metal-based TiC, there are many factors that affect the processing quality, and the determination of process parameters is complicated and troublesome, which makes the processed workpiece appear low surface quality, microstructure, non-uniform performance, and composition.

Defects such as segregation and obvious residual stress limit its application to a certain extent. The parameters that affect these factors are contradictory, such as hardness, laser scanning speed and laser power, beam diameter and laser power, and dilution rate and speed and power. The relationship between the information and the processing control parameters can ensure the stability and consistency of the performance of the laser cladding metal-based TiC coating. Establishment of multivariate complex coupling information regulation for laser cladding metal-based TiC is one of the research directions for future research. With the maturity of laser cladding metal-based TiC technology, the preparation of some higher performance and more stable cladding coatings on this basis is also the direction of future research.

Application prospect and research direction of laser cladding metal-based titanium carbide

Compared with other reinforcing phases, TiC has higher hardness and thermal stability, small thermal expansion coefficient, better toughness, and better wettability of nickel-based, especially titanium-based, and is widely used as laser cladding coating. The strengthening phase in . Titanium alloys and aluminum alloys have the advantages of high specific strength, good corrosion resistance and biocompatibility, and are widely used in aerospace, national defense, automotive, medical and other fields, but titanium alloys have high temperature oxidation resistance, thermal conductivity and The poor wear resistance greatly limits the application of titanium alloys in engineering. Cladding on the surface of alloys with better mechanical properties

The metal-based titanium carbide ceramic coating with high layer hardness, excellent oxidation resistance and wear resistance can greatly increase the application range of the alloy. Due to the high melting point of TiC, incomplete melting is prone to occur, and the incompletely melted powder is easy to adhere to the surface of the cladding layer and cause the surface to become rough. In the process of laser cladding metal-based TiC, there are many factors that affect the processing quality, and the determination of process parameters is complicated and troublesome, which makes the processed workpiece appear low surface quality, microstructure, non-uniform performance, and composition.

Defects such as segregation and obvious residual stress limit its application to a certain extent. The parameters that affect these factors are contradictory, such as hardness, laser scanning speed and laser power, beam diameter and laser power, and dilution rate and speed and power. The relationship between the information and the processing control parameters can ensure the stability and consistency of the performance of the laser cladding metal-based TiC coating. Establishment of multivariate complex coupling information regulation for laser cladding metal-based TiC is one of the research directions for future research. With the maturity of laser cladding metal-based TiC technology, the preparation of some higher performance and more stable cladding coatings on this basis is also the direction of future research.

related news

-

Mar 29, 2022Preparation method of titanium diboride

-

Feb 17, 2023Boron-containing Lithium ion battery electrolyte additive

Feb 17, 2023Boron-containing Lithium ion battery electrolyte additive -

Oct 25, 2021Comparison of different sintering methods of ZrC (zirconium carbide) ceramics and analysis of their application performance

Oct 25, 2021Comparison of different sintering methods of ZrC (zirconium carbide) ceramics and analysis of their application performance -

Oct 20, 2022Evaluation of the durability of ZrC as support material for Pt electrocatalysts in PEMFCs

Oct 20, 2022Evaluation of the durability of ZrC as support material for Pt electrocatalysts in PEMFCs