Preparation method of titanium diboride

Titanium diboride (TiB2) is a gray-black hexagonal crystal or powder with excellent overall performance, excellent thermal stability, oxidation resistance and electrical conductivity. TiB2 is used for hot-pressed ceramic products that require good electrical conductivity, industrial aluminum electrolytic cell cathode coating materials, hot-pressed titanium diboride + boron carbide composite bulletproof ceramic inserts, and titanium diboride-based cermet materials.

Preparation method of titanium diboride raw material

The current methods for preparing titanium diboride raw materials mainly include carbothermal reduction method, self-propagating high temperature and synthesis method, mechanochemical reaction method, vapor deposition method, ball milling method, etc.

①Carbothermal reduction method

Using titanium and boron oxides as raw materials, carbon black as a reducing agent, long-term high-temperature carbon reduction treatment in a carbon tube furnace, the purity of the synthesized titanium diboride powder depends on the purity of the raw material powder. This method is a process that is frequently used in industrial production. The disadvantage is that the obtained titanium diboride powder has a large particle size and a high impurity content.

②Self-propagating high-temperature synthesis (SHS)

This method is generally to press the raw material mixture to be reacted into a block and then ignite the reaction at one end of the block. The huge heat released by the reaction causes the adjacent materials to react, and finally, a combustion wave spreading at a speed v is formed. Finally, as the combustion wave advances, the raw material mixture is transformed into the final product. Due to the self-purification effect of the self-propagating high-temperature synthesis process, the product purity is high, so the obtained powder is easy to be further sintered, and the external energy consumption is low. If combined with other special technical means, dense titanium diboride can be directly prepared material.

③Mechanochemical reaction method (MR)

In this method, the reactant powder is placed in a high-energy ball mill, and the powder is repeatedly deformed to broken under the action of the squeezing and shearing of the grinding ball. The violent friction and collision of the ball milling medium cause the mechanical energy to be converted into chemical energy, thereby synthesizing the required reactants. Compared with the first two methods to prepare titanium diboride, the mechanochemical reaction method has the advantages of low synthesis temperature, wide source of raw materials and low cost.

.jpg)

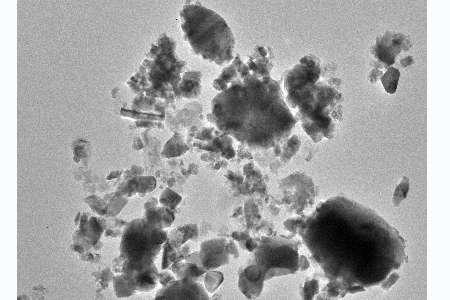

XRD of TiB2 powder

Preparation method of titanium diboride raw material

The current methods for preparing titanium diboride raw materials mainly include carbothermal reduction method, self-propagating high temperature and synthesis method, mechanochemical reaction method, vapor deposition method, ball milling method, etc.

①Carbothermal reduction method

Using titanium and boron oxides as raw materials, carbon black as a reducing agent, long-term high-temperature carbon reduction treatment in a carbon tube furnace, the purity of the synthesized titanium diboride powder depends on the purity of the raw material powder. This method is a process that is frequently used in industrial production. The disadvantage is that the obtained titanium diboride powder has a large particle size and a high impurity content.

②Self-propagating high-temperature synthesis (SHS)

This method is generally to press the raw material mixture to be reacted into a block and then ignite the reaction at one end of the block. The huge heat released by the reaction causes the adjacent materials to react, and finally, a combustion wave spreading at a speed v is formed. Finally, as the combustion wave advances, the raw material mixture is transformed into the final product. Due to the self-purification effect of the self-propagating high-temperature synthesis process, the product purity is high, so the obtained powder is easy to be further sintered, and the external energy consumption is low. If combined with other special technical means, dense titanium diboride can be directly prepared material.

③Mechanochemical reaction method (MR)

In this method, the reactant powder is placed in a high-energy ball mill, and the powder is repeatedly deformed to broken under the action of the squeezing and shearing of the grinding ball. The violent friction and collision of the ball milling medium cause the mechanical energy to be converted into chemical energy, thereby synthesizing the required reactants. Compared with the first two methods to prepare titanium diboride, the mechanochemical reaction method has the advantages of low synthesis temperature, wide source of raw materials and low cost.

.jpg)

XRD of TiB2 powder

related news

-

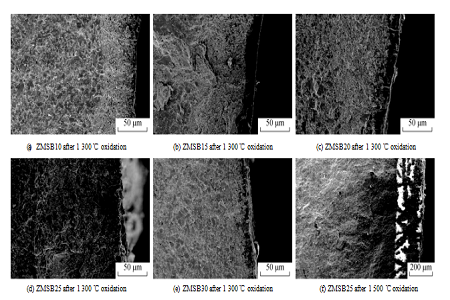

Dec 13, 2021Effect of Mo–Si–B on Sintering Process and Properties of ZrB2 Ultra-high-Temperature Ceramics

Dec 13, 2021Effect of Mo–Si–B on Sintering Process and Properties of ZrB2 Ultra-high-Temperature Ceramics -

.png) Nov 26, 2021The most common methods for producing zirconia (ZrO2) powder

Nov 26, 2021The most common methods for producing zirconia (ZrO2) powder -

Feb 16, 2022Properties and Applications of Titanium diboride(TiB2)

Feb 16, 2022Properties and Applications of Titanium diboride(TiB2) -

.png) May 26, 2022ZrB2-SiC composites prepared by adding silicon carbide (SiC)

May 26, 2022ZrB2-SiC composites prepared by adding silicon carbide (SiC)