The most common methods for producing zirconia (ZrO2) powder

Zirconium dioxide (ZrO2) micropowder is an important raw material in the field of high-tech ceramics and refractory materials. There are four mature methods for industrial powder production: plasma method, neutralization precipitation, hydrolysis precipitation and alkoxide hydrolysis.

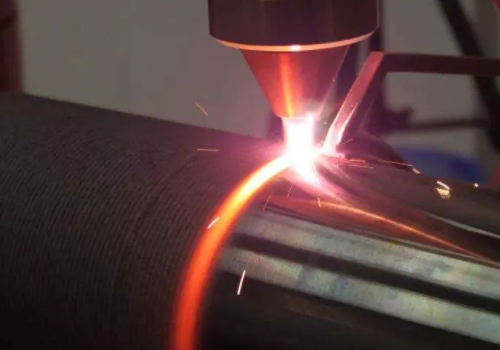

1. Plasma method

In 1969, the American Z-TECH company first successfully developed a method for extracting and purifying zirconia from zircon to produce high-purity monoclinic ZrO2 by using the ultra-high temperature generated by plasma arcs (Plasmaarcs), and obtained a patent.

Any gas will be significantly ionized when heated to 3000°C, and it will be almost completely ionized by 5500°C. Due to the electron flow after ionization, it can reach a very high temperature through resistance heating under the action of an electric field. This highly dissociated gas with high thermal conductivity is called plasma. The plasma cannot be obtained by heating the gas, but generally it is obtained by arc discharge. The simplest plasma generating device is an arc plasma spray gun. The principle is to apply a direct current voltage between two special electrodes, and at the same time pass a general inert gas (nitrogen, argon, helium or their mixture) between the electrodes. Then a stable DC arc is ignited between the two electrodes by means of high-frequency current or short-circuit, so that the gas continuously passing through the arc area absorbs energy to form a high-temperature plasma flame, which generates a high temperature of 80001500℃ and a high airflow velocity. The zircon fine powder sent into the flame is immediately decomposed into ZrO2 and SiO2, and the SiO2 is evaporated and separated from ZrO2, so as to achieve the purpose of preparing and purifying ZrO2.

The high-purity ZrO2 produced by the plasma method has unique properties. Plasma ZrO2 is spherical particles, and m-ZrO2 crystals are very fine. Practice has proved that the ZrO2 crystals formed at ultra-high temperatures have very high activity, which is very important for the manufacture of high-performance ceramic materials. The plasma process has also been continuously improved. The high-purity ZrO2 produced has a maximum ZrO2 content of 99.6%, and the particle size is above, and can be adjusted according to needs.

2. Neutralization precipitation method

The neutralization precipitation method is a method of preparing ZrO2 by precipitating hydrous zirconium oxide (also known as zirconium hydroxide gel) from the zirconium oxychloride (ZrOCl2) salt solution by using lye. The chemical reaction formula is:

ZrOCl2+2NH4OH+(n+1)H2O→Zr(OH)4·nH2O↓+2NH4Cl

First, dissolve ZrOCl2 in water to prepare a ZrOCl2·H2O solution, with a suitable concentration of 0.250.4mol/L. Ammonia water (NH4OH) was added to neutralize the precipitation reaction, the precipitate Zr(OH)4·nH2O was filtered, washed, dried at 100120℃, and finally calcined at 800℃×1 hour to obtain ZrO2 powder. Ammonia precipitation conditions have a significant effect on the properties (particle size, dispersion, purity, density) of ZrO2 particles. When it is desired to prepare CaO, MgO or Y2O3 stable ZrO2 powder, the co-precipitation method can be used. The stabilizer is added in the form of its salt solution. Generally, 3% (mol) of Y2O3 can be added to obtain partially stabilized ZrO2.

3. Hydrolysis precipitation method

The hydrolytic precipitation method is to boil the zirconium oxychloride solution for a long time to continuously evaporate and remove the HCl generated by the hydrolysis, so that the following hydrolysis reaction continues to proceed to the right to obtain the Zr(OH)4·nH2O precipitate:

ZrOCl2+(3+n)H2O→Zr(OH)4·nH2O↓+2HCl↑

The other process is the same as the neutralization precipitation method, but the ZrOCl2 concentration should be smaller, generally 0.20.3mol/L is more appropriate. This method has a simple process but high energy consumption.

4. Alkoxide hydrolysis

The alkoxide hydrolysis method is an effective method for preparing high-purity, ultra-fine ZrO2 powder. First, ZrCl2, C3H7OH, and liquid ammonia are reacted to synthesize zirconium alkoxide Zr(OC3H7)4 under the catalysis of benzene (C6H6). The reaction formula is as follows:

ZrCl4+4C3H7OH+4NH3→Zr(OC3H7)4+4NH4Cl

Remove NH4Cl by filtration to crystallize and purify Zr(OC3H7)4, and then add water for hydrolysis precipitation reaction:

Zr(OC3H7)4+2H2O→ZrO2+4C3H7OH

The precipitate is filtered out, dried at 100~110℃, pulverized, and calcined at 850℃ for 0.5 hours to obtain ZrO2 powder. Compared with the above two methods, the ZrO2 prepared by the alkoxide hydrolysis method has better powder characteristics: almost all ZrO2 is primary particles, rarely agglomerated secondary particles (agglomerates); particle size and shape are uniform; chemistry High purity and single phase structure. Therefore, the ZrO2 powder obtained by the hydrolysis of alkoxide is more suitable for manufacturing high-performance electronic materials and structural ceramics. However, the process conditions are complicated and the cost is relatively high.

1. Plasma method

In 1969, the American Z-TECH company first successfully developed a method for extracting and purifying zirconia from zircon to produce high-purity monoclinic ZrO2 by using the ultra-high temperature generated by plasma arcs (Plasmaarcs), and obtained a patent.

Any gas will be significantly ionized when heated to 3000°C, and it will be almost completely ionized by 5500°C. Due to the electron flow after ionization, it can reach a very high temperature through resistance heating under the action of an electric field. This highly dissociated gas with high thermal conductivity is called plasma. The plasma cannot be obtained by heating the gas, but generally it is obtained by arc discharge. The simplest plasma generating device is an arc plasma spray gun. The principle is to apply a direct current voltage between two special electrodes, and at the same time pass a general inert gas (nitrogen, argon, helium or their mixture) between the electrodes. Then a stable DC arc is ignited between the two electrodes by means of high-frequency current or short-circuit, so that the gas continuously passing through the arc area absorbs energy to form a high-temperature plasma flame, which generates a high temperature of 80001500℃ and a high airflow velocity. The zircon fine powder sent into the flame is immediately decomposed into ZrO2 and SiO2, and the SiO2 is evaporated and separated from ZrO2, so as to achieve the purpose of preparing and purifying ZrO2.

The high-purity ZrO2 produced by the plasma method has unique properties. Plasma ZrO2 is spherical particles, and m-ZrO2 crystals are very fine. Practice has proved that the ZrO2 crystals formed at ultra-high temperatures have very high activity, which is very important for the manufacture of high-performance ceramic materials. The plasma process has also been continuously improved. The high-purity ZrO2 produced has a maximum ZrO2 content of 99.6%, and the particle size is above, and can be adjusted according to needs.

2. Neutralization precipitation method

The neutralization precipitation method is a method of preparing ZrO2 by precipitating hydrous zirconium oxide (also known as zirconium hydroxide gel) from the zirconium oxychloride (ZrOCl2) salt solution by using lye. The chemical reaction formula is:

ZrOCl2+2NH4OH+(n+1)H2O→Zr(OH)4·nH2O↓+2NH4Cl

First, dissolve ZrOCl2 in water to prepare a ZrOCl2·H2O solution, with a suitable concentration of 0.250.4mol/L. Ammonia water (NH4OH) was added to neutralize the precipitation reaction, the precipitate Zr(OH)4·nH2O was filtered, washed, dried at 100120℃, and finally calcined at 800℃×1 hour to obtain ZrO2 powder. Ammonia precipitation conditions have a significant effect on the properties (particle size, dispersion, purity, density) of ZrO2 particles. When it is desired to prepare CaO, MgO or Y2O3 stable ZrO2 powder, the co-precipitation method can be used. The stabilizer is added in the form of its salt solution. Generally, 3% (mol) of Y2O3 can be added to obtain partially stabilized ZrO2.

3. Hydrolysis precipitation method

The hydrolytic precipitation method is to boil the zirconium oxychloride solution for a long time to continuously evaporate and remove the HCl generated by the hydrolysis, so that the following hydrolysis reaction continues to proceed to the right to obtain the Zr(OH)4·nH2O precipitate:

ZrOCl2+(3+n)H2O→Zr(OH)4·nH2O↓+2HCl↑

The other process is the same as the neutralization precipitation method, but the ZrOCl2 concentration should be smaller, generally 0.20.3mol/L is more appropriate. This method has a simple process but high energy consumption.

4. Alkoxide hydrolysis

The alkoxide hydrolysis method is an effective method for preparing high-purity, ultra-fine ZrO2 powder. First, ZrCl2, C3H7OH, and liquid ammonia are reacted to synthesize zirconium alkoxide Zr(OC3H7)4 under the catalysis of benzene (C6H6). The reaction formula is as follows:

ZrCl4+4C3H7OH+4NH3→Zr(OC3H7)4+4NH4Cl

Remove NH4Cl by filtration to crystallize and purify Zr(OC3H7)4, and then add water for hydrolysis precipitation reaction:

Zr(OC3H7)4+2H2O→ZrO2+4C3H7OH

The precipitate is filtered out, dried at 100~110℃, pulverized, and calcined at 850℃ for 0.5 hours to obtain ZrO2 powder. Compared with the above two methods, the ZrO2 prepared by the alkoxide hydrolysis method has better powder characteristics: almost all ZrO2 is primary particles, rarely agglomerated secondary particles (agglomerates); particle size and shape are uniform; chemistry High purity and single phase structure. Therefore, the ZrO2 powder obtained by the hydrolysis of alkoxide is more suitable for manufacturing high-performance electronic materials and structural ceramics. However, the process conditions are complicated and the cost is relatively high.

related news

-

Oct 28, 2022Carbide ultra-high temperature ceramics mainly include zirconium carbide (ZrC), tantalum carbide (TaC) and hafnium carbide (HfC),

Oct 28, 2022Carbide ultra-high temperature ceramics mainly include zirconium carbide (ZrC), tantalum carbide (TaC) and hafnium carbide (HfC), -

Jun 07, 2022application of nano TiN powder

Jun 07, 2022application of nano TiN powder -

Jan 17, 2022Laser Cladding Metal-Based Titanium Carbide Strengthening Coating

Jan 17, 2022Laser Cladding Metal-Based Titanium Carbide Strengthening Coating -

Nov 14, 2022physical properties of metal zirconium

Nov 14, 2022physical properties of metal zirconium