news center

-

.jpg) Silicon carbide, Boron carbide - the "king" of the bulletproof industrySilicon carbide ceramics have relatively low density and high hardness, and are structural ceramics with high cost performance. Therefore, they are also the most widely used bulletproof ceramics in China. Among these ceramics, boron carbide ceramics have the lowest density and the highest hardness, but at the same time, they have high requirements on processing technology and require high temperature and high pressure sintering, so the cost is also the highest among these three ceramics.more202201-12

Silicon carbide, Boron carbide - the "king" of the bulletproof industrySilicon carbide ceramics have relatively low density and high hardness, and are structural ceramics with high cost performance. Therefore, they are also the most widely used bulletproof ceramics in China. Among these ceramics, boron carbide ceramics have the lowest density and the highest hardness, but at the same time, they have high requirements on processing technology and require high temperature and high pressure sintering, so the cost is also the highest among these three ceramics.more202201-12 -

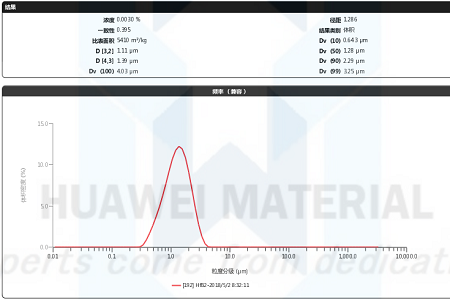

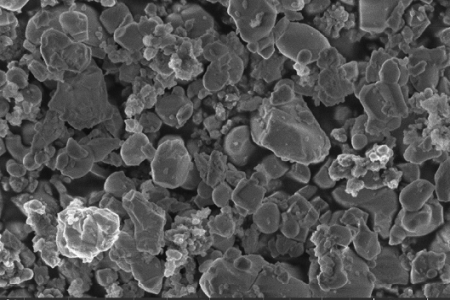

Investigation on Synthesis of Hafnium Diboride Powder by Reductive ReactionHigh pure hafnium diboride(HIB2)powders have been successfully prepared by the reaction of hafnium dioxide(Hf02)and boron carbide(B4C)in vacuum.The structure and morphology were characterized by X—ray diffraction(XRD) and scanning electron microscope(SEM).It shows that Hf02 and B4C call react with each other at 1 300 oC,and this iS in agreement with the result deduced from Gibbs free energy changes(AGaT)and Van Hough isothermal formula. The grain sizes of the synthesized. HfB2 increase with heat-treatment temperature and holding time,and the holding time have a greater influence on particle size.The crystallization of HfB2 powder were promoted by the excess of B4C and the crystallization level of HfB2 improved with B4C content increase.more202112-23

Investigation on Synthesis of Hafnium Diboride Powder by Reductive ReactionHigh pure hafnium diboride(HIB2)powders have been successfully prepared by the reaction of hafnium dioxide(Hf02)and boron carbide(B4C)in vacuum.The structure and morphology were characterized by X—ray diffraction(XRD) and scanning electron microscope(SEM).It shows that Hf02 and B4C call react with each other at 1 300 oC,and this iS in agreement with the result deduced from Gibbs free energy changes(AGaT)and Van Hough isothermal formula. The grain sizes of the synthesized. HfB2 increase with heat-treatment temperature and holding time,and the holding time have a greater influence on particle size.The crystallization of HfB2 powder were promoted by the excess of B4C and the crystallization level of HfB2 improved with B4C content increase.more202112-23 -

The development status of advanced carbide ceramic materials for aerospaceCarbide ultra-high temperature ceramics have good chemical and mechanical stability such as high melting point and good thermal shock resistance, and can adapt to extreme environments such as ultra-high sound speed long-term flight, atmospheric reentry, trans-atmospheric flight, and rocket propulsion systems. It is applied to various key parts such as the leading edge of the wing, the nose cone, and the hot end of the engine. At present, common carbide ultra-high temperature ceramics mainly include zirconium carbide (ZrC), tantalum carbide (TaC) and hafnium carbide (HfC), as well as ceramic matrix composite materials or multiphase materials based on them.more202112-16

The development status of advanced carbide ceramic materials for aerospaceCarbide ultra-high temperature ceramics have good chemical and mechanical stability such as high melting point and good thermal shock resistance, and can adapt to extreme environments such as ultra-high sound speed long-term flight, atmospheric reentry, trans-atmospheric flight, and rocket propulsion systems. It is applied to various key parts such as the leading edge of the wing, the nose cone, and the hot end of the engine. At present, common carbide ultra-high temperature ceramics mainly include zirconium carbide (ZrC), tantalum carbide (TaC) and hafnium carbide (HfC), as well as ceramic matrix composite materials or multiphase materials based on them.more202112-16 -

Research progress on preparation and properties of ultra-high temperature ceramic matrix compositesA review of the research system, preparation technology, material mechanics, oxidation resistance, and ablation resistance of the research system of ultra-high temperature ceramic matrix composites, focusing on carbide, boride ceramic matrix composites and continuous fiber toughened ceramic matrix composites System, briefly describe the sintered densification preparation process and the preparation method of continuous fiber toughened ceramic matrix composites, focus on explaining the influence of carbon fiber (Cf) on the mechanical properties of ZrB2-SiC composites at the microstructure level, and focus on the analysis of ZrC-SiC and ZrB2 The high-temperature oxidation resistance and ablation resistance of SiC composites provide an outlook on the challenges and development prospects of ultra-high-temperature ceramic matrix composites.more202112-15

Research progress on preparation and properties of ultra-high temperature ceramic matrix compositesA review of the research system, preparation technology, material mechanics, oxidation resistance, and ablation resistance of the research system of ultra-high temperature ceramic matrix composites, focusing on carbide, boride ceramic matrix composites and continuous fiber toughened ceramic matrix composites System, briefly describe the sintered densification preparation process and the preparation method of continuous fiber toughened ceramic matrix composites, focus on explaining the influence of carbon fiber (Cf) on the mechanical properties of ZrB2-SiC composites at the microstructure level, and focus on the analysis of ZrC-SiC and ZrB2 The high-temperature oxidation resistance and ablation resistance of SiC composites provide an outlook on the challenges and development prospects of ultra-high-temperature ceramic matrix composites.more202112-15 -

.png) Ultra-high temperature materialsUltra-high temperature materials play an important role in aerospace vehicles. They are an indispensable part of the aircraft in long-term flight, transatmosphere or reentry flight, and play a vital role in the aircraft's thermal protection system. This paper summarizes and summarizes the latest research results of refractory metals and their alloys, C/C composite materials, ultra-high temperature ceramics and other ultra-high temperature materials in recent years, analyzes the advantages and disadvantages of ultra-high temperature materials, puts forward the main problems, and discusses the future Main research goals and key development directions.more202112-08

Ultra-high temperature materialsUltra-high temperature materials play an important role in aerospace vehicles. They are an indispensable part of the aircraft in long-term flight, transatmosphere or reentry flight, and play a vital role in the aircraft's thermal protection system. This paper summarizes and summarizes the latest research results of refractory metals and their alloys, C/C composite materials, ultra-high temperature ceramics and other ultra-high temperature materials in recent years, analyzes the advantages and disadvantages of ultra-high temperature materials, puts forward the main problems, and discusses the future Main research goals and key development directions.more202112-08 -

Chemical preparation method of nano powderThe preparation method of nano powder has always been a hot technology in the powder industry. Our common powder processing is mechanical crushing processing method. However, this processing method is usually very difficult to be competent for the production and processing of nano powders, and it is difficult to find suitable crushing equipment. This article will introduce a special kind of nano powder processing technology-chemical method.more202111-30

Chemical preparation method of nano powderThe preparation method of nano powder has always been a hot technology in the powder industry. Our common powder processing is mechanical crushing processing method. However, this processing method is usually very difficult to be competent for the production and processing of nano powders, and it is difficult to find suitable crushing equipment. This article will introduce a special kind of nano powder processing technology-chemical method.more202111-30