news center

-

Research on ultra-high temperature ceramic materials(1)Ultra-high temperature ceramics (UHTCs) have become one of the potential strategic materials in the fields of future hypersonic flights and reusable launch vehicles due to their excellent physical and chemical properties in the extreme environments. The paper reviews new developments of techniques for UHTCs. include materials system,synthesis of powders, sintering and coatings. The problems in the material research and applications were preliminarily summarized and coatings of UHTCs is one of the trends was pointed out.more202202-28

Research on ultra-high temperature ceramic materials(1)Ultra-high temperature ceramics (UHTCs) have become one of the potential strategic materials in the fields of future hypersonic flights and reusable launch vehicles due to their excellent physical and chemical properties in the extreme environments. The paper reviews new developments of techniques for UHTCs. include materials system,synthesis of powders, sintering and coatings. The problems in the material research and applications were preliminarily summarized and coatings of UHTCs is one of the trends was pointed out.more202202-28 -

Research progress of B4C-TiB2 composite ceramic materials(2)The composite composite ceramic material (B4C-TiB2) can not only improve the sintering performance of B4C, increase the density, but also improve the fracture toughness and strength of the material. Therefore, B4C -TiB2 composite ceramic material has more application value.more202202-18

Research progress of B4C-TiB2 composite ceramic materials(2)The composite composite ceramic material (B4C-TiB2) can not only improve the sintering performance of B4C, increase the density, but also improve the fracture toughness and strength of the material. Therefore, B4C -TiB2 composite ceramic material has more application value.more202202-18 -

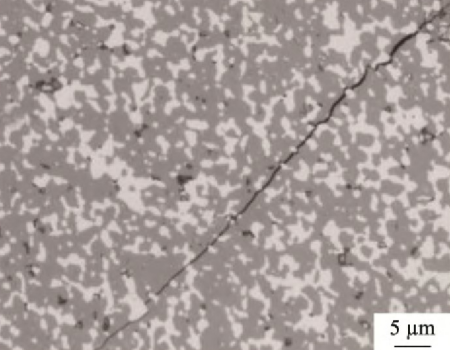

Research progress of B4C-TiB2 composite ceramic materials(1)B4C-TiB2 multiphase ceramic material not only has the high hardness and low density of B4C, but also has the high toughness and electrical conductivity of TiB2. Simultaneously obtaining high toughness and high hardness in such materials has always been an urgent need in the field of materials, and it is also a great challenge. In view of the increasing abundance of B4C-TiB2 composite ceramic materials in recent years, focusing on three key factors such as the density and toughening phase content of B4C-TiB2 composite materials, grain size, and third phase components, the current The research progress of B4C-TiB2 composite ceramic materials is described. It is considered that high density and appropriate toughening phase content (≤15%) are necessary conditions to obtain balanced hardness and toughness; grain refinement can promote the strengthening of grain boundaries between B4C and TiB2 and the increase of intergranular fracture modes, which in turn increase The hardness and toughness of the material; the introduction of the third phase component contributes to the improvement of the material density and the optimization of the microstructure, thereby improving the hardness and toughness of the B4C-TiB2 composite ceramic material.more202202-09

Research progress of B4C-TiB2 composite ceramic materials(1)B4C-TiB2 multiphase ceramic material not only has the high hardness and low density of B4C, but also has the high toughness and electrical conductivity of TiB2. Simultaneously obtaining high toughness and high hardness in such materials has always been an urgent need in the field of materials, and it is also a great challenge. In view of the increasing abundance of B4C-TiB2 composite ceramic materials in recent years, focusing on three key factors such as the density and toughening phase content of B4C-TiB2 composite materials, grain size, and third phase components, the current The research progress of B4C-TiB2 composite ceramic materials is described. It is considered that high density and appropriate toughening phase content (≤15%) are necessary conditions to obtain balanced hardness and toughness; grain refinement can promote the strengthening of grain boundaries between B4C and TiB2 and the increase of intergranular fracture modes, which in turn increase The hardness and toughness of the material; the introduction of the third phase component contributes to the improvement of the material density and the optimization of the microstructure, thereby improving the hardness and toughness of the B4C-TiB2 composite ceramic material.more202202-09 -

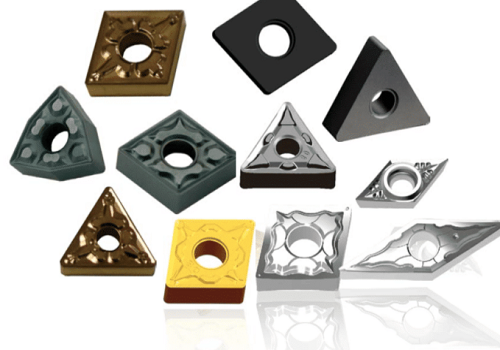

Properties and applications of common carbidesThe so-called carbide refers to a binary compound formed by carbon and an element with a smaller electronegativity or a similar element (except hydrogen), and the carbide has a relatively high melting point. obtained by reaction at high temperature. Carbide has high temperature resistance, wear resistance, corrosion resistance and good electrical conductivity. It is widely used in the production of ceramics, cutting tools, wear-resistant materials and other fields. In recent years, carbide has also shown good performance in the field of catalysis. Carbide materials are widely used in industrial production of alloys due to their unique strength and stability, and their performance determines their application. Let's take a look at the properties of common carbides!more202201-25

Properties and applications of common carbidesThe so-called carbide refers to a binary compound formed by carbon and an element with a smaller electronegativity or a similar element (except hydrogen), and the carbide has a relatively high melting point. obtained by reaction at high temperature. Carbide has high temperature resistance, wear resistance, corrosion resistance and good electrical conductivity. It is widely used in the production of ceramics, cutting tools, wear-resistant materials and other fields. In recent years, carbide has also shown good performance in the field of catalysis. Carbide materials are widely used in industrial production of alloys due to their unique strength and stability, and their performance determines their application. Let's take a look at the properties of common carbides!more202201-25 -

Structural Properties and Bonding Strength of Titanium carbonitride CoatingsTitanium carbonitride coating has excellent mechanical and tribological properties. As a hard wear-resistant coating, it has been widely used in cutting tools, drills and molds, and has wide application prospects. The research shows that the structure, properties and bonding strength of the Titanium carbonitride coating are affected by factors such as chemical composition and process parameters.more202201-24

Structural Properties and Bonding Strength of Titanium carbonitride CoatingsTitanium carbonitride coating has excellent mechanical and tribological properties. As a hard wear-resistant coating, it has been widely used in cutting tools, drills and molds, and has wide application prospects. The research shows that the structure, properties and bonding strength of the Titanium carbonitride coating are affected by factors such as chemical composition and process parameters.more202201-24 -

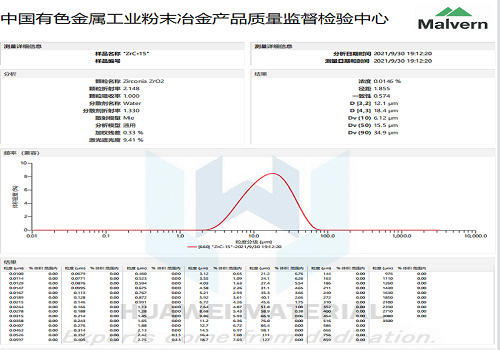

Chemical vapor deposition of zirconium carbide coatingsRefractory compounds such as ZrC. HfC,TaC,ZrB2, HfB2, the melting point are more than 3000 ℃, which are the high heat resistance compounds. CVD - ZrC coating has widely industrial application and there are lots of work to do with the related research.more202201-19

Chemical vapor deposition of zirconium carbide coatingsRefractory compounds such as ZrC. HfC,TaC,ZrB2, HfB2, the melting point are more than 3000 ℃, which are the high heat resistance compounds. CVD - ZrC coating has widely industrial application and there are lots of work to do with the related research.more202201-19