Influencing Factors of Preparation of Ultra-fine Zirconium Diboride Powders

Influencing Factors of Preparation of Ultra-fine Zirconium Diboride Powders

As one of the basic materials in the high temperature field in the 21st century, ZrB2 is an important ultra-high temperature ceramic material. ZrB2 ceramics are used in thermal barrier coating materials, high-temperature structural ceramic materials, composite materials due to their excellent characteristics such as high melting point, high strength, high hardness, excellent electrical and thermal conductivity, and good flame retardancy, corrosion resistance, and concentration trapping. , Electrode materials, thin film materials, refractory materials, nuclear control materials and other fields have been widely developed and used.

At present, the industrial preparation of ZrBz powder mostly adopts the gas phase method and the solid phase method. The gas phase method is mainly used to prepare ZrB? thin films and coatings, the synthesis process is slow, and the raw materials are expensive; the solid phase method uses micron-sized powder as its raw material, so the obtained powder has a relatively large particle size and poor sintering activity . In order to obtain ultra-fine ZrB? powder, Wang Baina and others used the basic principle of the carbothermic reduction of the Zr02-B203-C reaction system and used the sol-gel coordinated carbothermic reduction method to obtain a particle size distribution of 0.2-0.6 |xm. The ultrafine zirconium boride powder with a specific surface area of 74 m2/g, the particles are spherical or quasi-spherical.

In order to further study the influencing factors of the preparation of ultra-fine ZrB2 by the sol-gel synergistic carbothermic reduction method, this article separately analyzed the ratio of Zr and citric acid, the sol-gel temperature, the pH value of the system and the content of dispersant to the ZrBz precursor, and the influence of pyrolysis products.

Results and discussion

Phase analysis

.png)

Figure 1 shows the XRD pattern of ZrB2 powder obtained with boron ratio (amount of substance)=3.5, ratio of carbon to carbon (amount of substance)=12.5, pyrolysis temperature 1600 Y, and pyrolysis time 2 h. As shown in Figure 1, the experimental results show that the obtained ZrB2 has a C32 type hexagonal structure without impurities.

Infrared spectroscopy analysis

The influence of the molar ratio of Zr 4+and citric acid (r) on the precursor Figure 2 shows the infrared spectrum of the ZrB? precursor obtained when the ratio of Zr4+and citric acid is different. According to relevant literature reports, the main functional groups contained in the precursor are: Zr-0, Zr-0-Zr[57]o Zr-0-Zr, Zr-0 is a lemon formed by citric acid complexed with Zr in the solution The chain structure of acid-alumina, and the wave numbers are 850 cm-\600 cm" and 520 cm". When "= 3, Figure 2(a) has only one width between the wave number 900 -500 cm"

The peak appears when r = 2 and r = 1, the vibration peaks of Zr-O-Zr.Zr-O in Figure 2 (b) and (c) are clearer and identifiable. During the experiment, when the lemons acid content increases in the system, the colloid changes from transparent to milky white. It can be judged that the milky white substance is a gel formed by hydrogen bonding between Zr4+ citric acid complex molecules. Therefore, as the content of citric acid increases, the complexation reaction becomes more complete and a milky white colloid is formed, and the vibration peaks of Zr-O-Zr and Zr-0 also appear in the spectrum. In addition, the absorption peak at 1086 mark-' in the spectrum should be the C-0 stretching vibration peak ⑻ connected to ZL. When r = 2, the vibration peak reaches the strongest.

.png)

The effect of pH on precursors

When r=2, Figure 3 shows the infrared spectrum of ZrB: precursor obtained when the pH of the system is different, and Figure 3(a) is the infrared spectrum of citric acid. During the experiment, with the gradual addition of ammonia water, a milky white precipitate was produced and then became transparent. This is because after adding ammonia water of the same equivalent as citric acid, continue to adjust the pH value, zr4+ will be completely acidified with citric acid after citric acid hydrolysis Coordination and binding are neutral and produce precipitation. When the system is basic, zr4+ will bind a certain amount of hydroxyl groups, and the complex will be negatively charged, and then dissolve and become transparent. 1720 om in Figure 3(a). 1. There are characteristic peaks of citric acid nearby:. The C=O of COOH is anti-symmetric stretching vibration. Compared with Figure 3(b), (e), (d), it is found that the characteristic peak shifts after citric acid is complexed with zr4+, and as the pH value increases, this peak gradually widens and the intensity gradually weakens. The vibration peak at 1667 om in Figure 3 (b), (c), (d) is: the carbonyl vibration in C00 one complexed with zr4+ is j, the vibration peak first increases and then decreases with the increase of pH The trend is strongest at pH=4. It shows that the ionization degree of citric acid will increase with the increase of the pH value of the solution. Dropping an appropriate amount of ammonia can promote the complexation reaction and help to form a stable colloid. This is also reported in the literature [10]. But when pH=8, the stretching vibration peaks of Zr-O and Zr-O-Zr in Figure 3(d) weaken or even disappear, that is, when the solution is alkaline, it is not conducive to the complex reaction between zr4+ and citric acid. When pH=4, there is a stable complex in the system.

ZrB2 powder particle size analysis

.png)

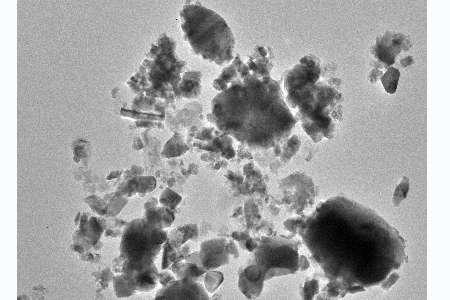

In the figure (a) and (b) are respectively when r=2, pH=4, T=50 ℃ and when r=2, pH=4, T=50 ℃, c=2% prepared under the conditions of ZrB2 powder The particle size distribution diagram of the body. Table 1 is its corresponding ZrB: powder particle size characteristic parameters. Combining Figure 6 and Table 1, it can be seen that the particle size of ZrB powder in Figure 6(a) is mainly distributed between 150 and 430 nm, D=260 nm, and the particle size distribution of the powder is uniform, which is similar to that of Figure 4(a). The particle size distribution of the powder is basically the same; in Figure (b), the particle size of the ZrB2 powder is mainly distributed between 150 and 280 nm, with D=190 nm. After adding an appropriate amount of dispersant PEG, the particle size distribution range of the powder is further reduced.

Conclusion

In this paper, the sol is studied experimentally. The influencing factors of the preparation of ultrafine ZrB2 by the gel-assisted carbothermic reduction method. Studies have shown that: r=2 and pH=4 are the best conditions for the complex reaction of citric acid and zr4+; when sol. When the gel temperature is 50℃, the product is basically spherical or quasi-spherical, and the particle size distribution of the powder is uniform; polyethylene glycol exists as a chain structure in the solution, which can greatly improve the dispersion of the powder by coating on the surface of the colloidal particles In addition, polyethylene glycol can “guide” the cross-linking of clusters in the sol, so that the pyrolyzed crystal grains are arranged in an orderly manner. In addition, when the polyethylene glycol content is 2%, a product with good dispersibility and uniform size can be obtained.

(This article is original from :Faculty of Material Science and Engineefing,Kunming University of Science and Technolog.)

As one of the basic materials in the high temperature field in the 21st century, ZrB2 is an important ultra-high temperature ceramic material. ZrB2 ceramics are used in thermal barrier coating materials, high-temperature structural ceramic materials, composite materials due to their excellent characteristics such as high melting point, high strength, high hardness, excellent electrical and thermal conductivity, and good flame retardancy, corrosion resistance, and concentration trapping. , Electrode materials, thin film materials, refractory materials, nuclear control materials and other fields have been widely developed and used.

At present, the industrial preparation of ZrBz powder mostly adopts the gas phase method and the solid phase method. The gas phase method is mainly used to prepare ZrB? thin films and coatings, the synthesis process is slow, and the raw materials are expensive; the solid phase method uses micron-sized powder as its raw material, so the obtained powder has a relatively large particle size and poor sintering activity . In order to obtain ultra-fine ZrB? powder, Wang Baina and others used the basic principle of the carbothermic reduction of the Zr02-B203-C reaction system and used the sol-gel coordinated carbothermic reduction method to obtain a particle size distribution of 0.2-0.6 |xm. The ultrafine zirconium boride powder with a specific surface area of 74 m2/g, the particles are spherical or quasi-spherical.

In order to further study the influencing factors of the preparation of ultra-fine ZrB2 by the sol-gel synergistic carbothermic reduction method, this article separately analyzed the ratio of Zr and citric acid, the sol-gel temperature, the pH value of the system and the content of dispersant to the ZrBz precursor, and the influence of pyrolysis products.

Results and discussion

Phase analysis

.png)

Figure 1 shows the XRD pattern of ZrB2 powder obtained with boron ratio (amount of substance)=3.5, ratio of carbon to carbon (amount of substance)=12.5, pyrolysis temperature 1600 Y, and pyrolysis time 2 h. As shown in Figure 1, the experimental results show that the obtained ZrB2 has a C32 type hexagonal structure without impurities.

Infrared spectroscopy analysis

The influence of the molar ratio of Zr 4+and citric acid (r) on the precursor Figure 2 shows the infrared spectrum of the ZrB? precursor obtained when the ratio of Zr4+and citric acid is different. According to relevant literature reports, the main functional groups contained in the precursor are: Zr-0, Zr-0-Zr[57]o Zr-0-Zr, Zr-0 is a lemon formed by citric acid complexed with Zr in the solution The chain structure of acid-alumina, and the wave numbers are 850 cm-\600 cm" and 520 cm". When "= 3, Figure 2(a) has only one width between the wave number 900 -500 cm"

The peak appears when r = 2 and r = 1, the vibration peaks of Zr-O-Zr.Zr-O in Figure 2 (b) and (c) are clearer and identifiable. During the experiment, when the lemons acid content increases in the system, the colloid changes from transparent to milky white. It can be judged that the milky white substance is a gel formed by hydrogen bonding between Zr4+ citric acid complex molecules. Therefore, as the content of citric acid increases, the complexation reaction becomes more complete and a milky white colloid is formed, and the vibration peaks of Zr-O-Zr and Zr-0 also appear in the spectrum. In addition, the absorption peak at 1086 mark-' in the spectrum should be the C-0 stretching vibration peak ⑻ connected to ZL. When r = 2, the vibration peak reaches the strongest.

.png)

The effect of pH on precursors

When r=2, Figure 3 shows the infrared spectrum of ZrB: precursor obtained when the pH of the system is different, and Figure 3(a) is the infrared spectrum of citric acid. During the experiment, with the gradual addition of ammonia water, a milky white precipitate was produced and then became transparent. This is because after adding ammonia water of the same equivalent as citric acid, continue to adjust the pH value, zr4+ will be completely acidified with citric acid after citric acid hydrolysis Coordination and binding are neutral and produce precipitation. When the system is basic, zr4+ will bind a certain amount of hydroxyl groups, and the complex will be negatively charged, and then dissolve and become transparent. 1720 om in Figure 3(a). 1. There are characteristic peaks of citric acid nearby:. The C=O of COOH is anti-symmetric stretching vibration. Compared with Figure 3(b), (e), (d), it is found that the characteristic peak shifts after citric acid is complexed with zr4+, and as the pH value increases, this peak gradually widens and the intensity gradually weakens. The vibration peak at 1667 om in Figure 3 (b), (c), (d) is: the carbonyl vibration in C00 one complexed with zr4+ is j, the vibration peak first increases and then decreases with the increase of pH The trend is strongest at pH=4. It shows that the ionization degree of citric acid will increase with the increase of the pH value of the solution. Dropping an appropriate amount of ammonia can promote the complexation reaction and help to form a stable colloid. This is also reported in the literature [10]. But when pH=8, the stretching vibration peaks of Zr-O and Zr-O-Zr in Figure 3(d) weaken or even disappear, that is, when the solution is alkaline, it is not conducive to the complex reaction between zr4+ and citric acid. When pH=4, there is a stable complex in the system.

ZrB2 powder particle size analysis

.png)

In the figure (a) and (b) are respectively when r=2, pH=4, T=50 ℃ and when r=2, pH=4, T=50 ℃, c=2% prepared under the conditions of ZrB2 powder The particle size distribution diagram of the body. Table 1 is its corresponding ZrB: powder particle size characteristic parameters. Combining Figure 6 and Table 1, it can be seen that the particle size of ZrB powder in Figure 6(a) is mainly distributed between 150 and 430 nm, D=260 nm, and the particle size distribution of the powder is uniform, which is similar to that of Figure 4(a). The particle size distribution of the powder is basically the same; in Figure (b), the particle size of the ZrB2 powder is mainly distributed between 150 and 280 nm, with D=190 nm. After adding an appropriate amount of dispersant PEG, the particle size distribution range of the powder is further reduced.

Conclusion

In this paper, the sol is studied experimentally. The influencing factors of the preparation of ultrafine ZrB2 by the gel-assisted carbothermic reduction method. Studies have shown that: r=2 and pH=4 are the best conditions for the complex reaction of citric acid and zr4+; when sol. When the gel temperature is 50℃, the product is basically spherical or quasi-spherical, and the particle size distribution of the powder is uniform; polyethylene glycol exists as a chain structure in the solution, which can greatly improve the dispersion of the powder by coating on the surface of the colloidal particles In addition, polyethylene glycol can “guide” the cross-linking of clusters in the sol, so that the pyrolyzed crystal grains are arranged in an orderly manner. In addition, when the polyethylene glycol content is 2%, a product with good dispersibility and uniform size can be obtained.

(This article is original from :Faculty of Material Science and Engineefing,Kunming University of Science and Technolog.)

.png)