RELATED cases

| Model | APS(D50) | Purity(%) | O(%) | N(%) | C(%) | Si(%) |

| MoSi2 0800 | 0.5-1.0um | >99.0 | ≤1.0 | ≤0.10 | ≤0.1 | 33.2~36.9 |

| MoSi2 0020 | 1.0-3.0um | >99.5 | ≤.0.8 | ≤0.10 | ≤0.1 | 33.2~36.9 |

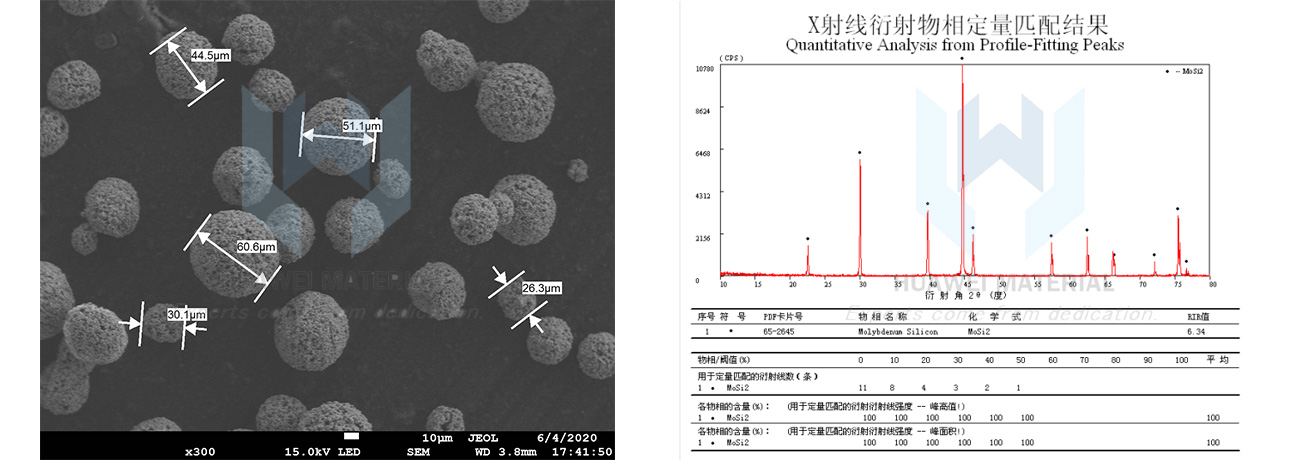

| MoSi2 0003 | 10.0-60.0um | >99.9 | ≤0.50 | ≤0.05 | ≤0.1 | 33.2~36.9 |

| MoSi2 0008 | -325mesh | >99.9 | ≤0.30 | ≤0.05 | ≤0.1 | 33.2~36.9 |

| Customized chemical composition and particle size can be made according to customer requirements. | ||||||

| Model | APS(D50) | Size Distribution Range |

| MoSi2 0800 | 0.5-1.0um | Type 1:D50<1.0um,Type 2:D90<1.0um |

| MoSi2 0020 MoSi2 0021 |

1.0-3.0um | Type 1:D50:1.0~3.0um,D90:3.5-4.5um Type 2:<1.0um≯10%,>3.0um≯10%,1.0-3.0um≥80% |

| MoSi2 0003 | 10.0-60.0um | <10.0um≯10%,>60.0um≯5%,10-60um≥80%,Spherical or nearly spherical |