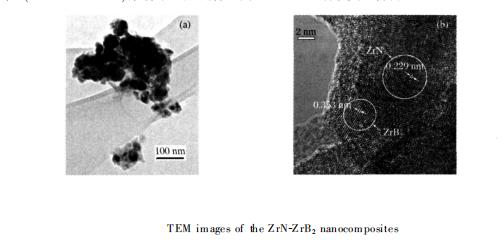

Characterization of ZrN-ZrB2 nanocomposites

Zirconium nitride ( ZrN ) has high melting point ( 2 980 ℃ ), high hardness (about 13 GPa ), high bulk elastic modulus ( 328 GPa ), high thermal conductivity ( 20.5 W/ ( m · K) ), low Resistivity (13.6 μΨ·cm), good chemical and thermal stability, excellent mechanical/abrasion properties, and color similar to gold, etc., can be used as a wear-resistant and corrosion-resistant layer in the mechanical industry, and can be used in the electronics industry. As an electrical contact layer, it can be used as a decorative film in the jewelry industry.

Since both ZrN and ZrB2 belong to covalent bond compounds with high melting point, the diffusion coefficient is very small at high temperature, and high sintering temperature (above 1850 ℃) is required to densify them. Scholars at home and abroad have used various sintering processes to study the densification of ZrN and ZrB2 materials in order to improve the comprehensive properties of the materials.

Combining the high bulk elastic modulus and excellent electrical conductivity of ZrB2 with the corrosion resistance and high temperature oxidation resistance of ZrN to achieve complementary advantages, it is expected to produce composite materials with excellent mechanical and electrical properties.

Since both ZrN and ZrB2 belong to covalent bond compounds with high melting point, the diffusion coefficient is very small at high temperature, and high sintering temperature (above 1850 ℃) is required to densify them. Scholars at home and abroad have used various sintering processes to study the densification of ZrN and ZrB2 materials in order to improve the comprehensive properties of the materials.

Combining the high bulk elastic modulus and excellent electrical conductivity of ZrB2 with the corrosion resistance and high temperature oxidation resistance of ZrN to achieve complementary advantages, it is expected to produce composite materials with excellent mechanical and electrical properties.

related news

-

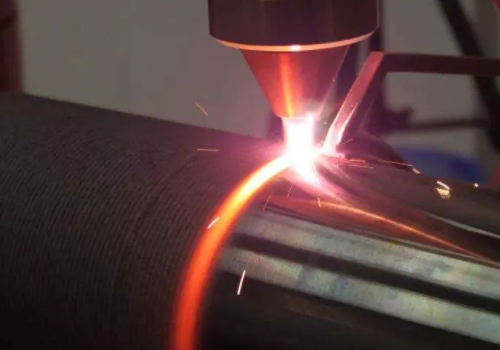

Jan 17, 2022Laser Cladding Metal-Based Titanium Carbide Strengthening Coating

Jan 17, 2022Laser Cladding Metal-Based Titanium Carbide Strengthening Coating -

(1).png) Oct 08, 2021Ultra-high temperature ceramics help high-speed aircraft withstand the high temperature of 2000 ℃!

Oct 08, 2021Ultra-high temperature ceramics help high-speed aircraft withstand the high temperature of 2000 ℃! -

.jpg) Nov 05, 2021Influencing Factors of Preparation of Ultra-fine Zirconium Diboride Powders

Nov 05, 2021Influencing Factors of Preparation of Ultra-fine Zirconium Diboride Powders -

.png) Oct 18, 2021What high-value potential applications does titanium carbide have after nanometerization?

Oct 18, 2021What high-value potential applications does titanium carbide have after nanometerization?