news center

-

.png) Effect of ZrC-doping on Microstructural and Mechanical Properties of ZTA Ceramic CompositesEffect of ZrC-doping (i.e., 10%, 15%, 20%, and 25%) on the microstructural and mechanical properties of ZTA20% (zirconia-20% toughened alumina) ceramic composites was investigated. The samples were prepared via spark plasma sintering (SPS) at 1 400 ℃ and 40 MPa for a soaking time of 15 min. The relative density of samples measured by the Archimedes method is 99.08%. Based on the results by X-ray diffraction, the phases of the sintered samples are ZrC, α-Al2O3 and ZrO2, which are the same as the raw powders, indicating that no impurity phase is formed after sintering, and the ceramic composites have excellent chemical compatibility during sintering. According to the cross-sectional images by scanning electron microscopy, the size of various grains in the composites is uniform. Moreover, the fracture mechanism is combined with transgranular and intergranular fractures. The flexural strength first increases and then decreases with the increase of ZrC doping, thus being its maximum value of 722 MPa at 20% ZrC. The fracture toughness increases monotonically from 5.47 to 6.51 MPa·m1/2 as ZrC content increases. The microhardness of the sample is inversely proportional to ZrC content, which decreases from 17.30 to 16.19 GPa.more202112-10

Effect of ZrC-doping on Microstructural and Mechanical Properties of ZTA Ceramic CompositesEffect of ZrC-doping (i.e., 10%, 15%, 20%, and 25%) on the microstructural and mechanical properties of ZTA20% (zirconia-20% toughened alumina) ceramic composites was investigated. The samples were prepared via spark plasma sintering (SPS) at 1 400 ℃ and 40 MPa for a soaking time of 15 min. The relative density of samples measured by the Archimedes method is 99.08%. Based on the results by X-ray diffraction, the phases of the sintered samples are ZrC, α-Al2O3 and ZrO2, which are the same as the raw powders, indicating that no impurity phase is formed after sintering, and the ceramic composites have excellent chemical compatibility during sintering. According to the cross-sectional images by scanning electron microscopy, the size of various grains in the composites is uniform. Moreover, the fracture mechanism is combined with transgranular and intergranular fractures. The flexural strength first increases and then decreases with the increase of ZrC doping, thus being its maximum value of 722 MPa at 20% ZrC. The fracture toughness increases monotonically from 5.47 to 6.51 MPa·m1/2 as ZrC content increases. The microhardness of the sample is inversely proportional to ZrC content, which decreases from 17.30 to 16.19 GPa.more202112-10 -

.png) Titanium Diboride(TiB2): A New Type of Industrial Ceramic MaterialAmong many compounds, metal borides have better high temperature performance than metal carbides. For example, titanium diboride (TiB2) cermet products are more suitable than titanium carbide (TiC) and tungsten carbide (WC) cermet products while using under high temperature and high corrosive working conditions. Titanium diboride powder is gray (or gray-black) and ranks sixth among the top ten materials with the highest melting point in the world currently known . The anti-oxidation temperature in the air can reach 1100℃. As a new type of ceramic material, it has excellent physical and chemical properties. The current methods for preparing titanium diboride raw materials mainly include carbothermic reduction method, self-propagating high temperature and synthesis method, mechanochemical reaction method, vapor deposition method, ball milling method, etc.more202112-06

Titanium Diboride(TiB2): A New Type of Industrial Ceramic MaterialAmong many compounds, metal borides have better high temperature performance than metal carbides. For example, titanium diboride (TiB2) cermet products are more suitable than titanium carbide (TiC) and tungsten carbide (WC) cermet products while using under high temperature and high corrosive working conditions. Titanium diboride powder is gray (or gray-black) and ranks sixth among the top ten materials with the highest melting point in the world currently known . The anti-oxidation temperature in the air can reach 1100℃. As a new type of ceramic material, it has excellent physical and chemical properties. The current methods for preparing titanium diboride raw materials mainly include carbothermic reduction method, self-propagating high temperature and synthesis method, mechanochemical reaction method, vapor deposition method, ball milling method, etc.more202112-06 -

Preparation and application of titanium carbide-based cermetTitanium carbide-based cermet is a heterogeneous composite material composed of a metal or alloy TiC ceramic phase, which combines the high strength, high hardness, wear resistance, high temperature resistance, oxidation resistance and chemical stability of ceramics, as well as metal The toughness can be used to make high-temperature thermocouple protective sleeves and crucibles for smelting metals used in reducing and inert atmospheres.

Preparation and application of titanium carbide-based cermetTitanium carbide-based cermet is a heterogeneous composite material composed of a metal or alloy TiC ceramic phase, which combines the high strength, high hardness, wear resistance, high temperature resistance, oxidation resistance and chemical stability of ceramics, as well as metal The toughness can be used to make high-temperature thermocouple protective sleeves and crucibles for smelting metals used in reducing and inert atmospheres.

Preparation processes including Chemical vapor deposition (CVD),Physical vapor deposition (PVD),Liquid deposition,Thermal spraying,In-situ synthesis method,etc,.

more202112-02 -

.png) The most common methods for producing zirconia (ZrO2) powderZirconium dioxide (ZrO2) micropowder is an important raw material in the field of high-tech ceramics and refractory materials. There are four mature methods for industrial powder production: plasma method, neutralization precipitation, hydrolysis precipitation and alkoxide hydrolysis.more202111-26

The most common methods for producing zirconia (ZrO2) powderZirconium dioxide (ZrO2) micropowder is an important raw material in the field of high-tech ceramics and refractory materials. There are four mature methods for industrial powder production: plasma method, neutralization precipitation, hydrolysis precipitation and alkoxide hydrolysis.more202111-26 -

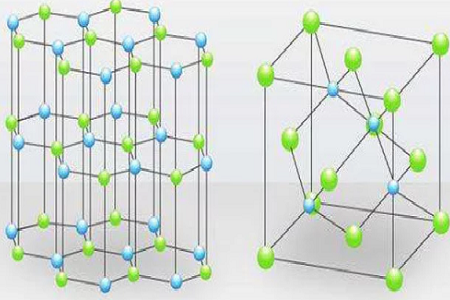

Preparation and Application of Boron Nitride (BN) MaterialsBoron nitride (BN) is an important group III element composed of group III element boron (B) and group V element nitrogen (N). Group V compounds. Boron nitride has excellent physical and chemical properties such as wide band gap, high thermal conductivity, and oxidation resistance. Boron nitride also has great application prospects in terms of high temperature, high frequency, high power, optoelectronics and radiation resistance. Therefore, the preparation of boron nitride nanomaterials, the measurement of nanostructures, the assembly of nanodevices, the testing of boron nitride toughened ceramics and optical and electrical properties have become important research directions in the field of inorganic nanomaterials.more202111-22

Preparation and Application of Boron Nitride (BN) MaterialsBoron nitride (BN) is an important group III element composed of group III element boron (B) and group V element nitrogen (N). Group V compounds. Boron nitride has excellent physical and chemical properties such as wide band gap, high thermal conductivity, and oxidation resistance. Boron nitride also has great application prospects in terms of high temperature, high frequency, high power, optoelectronics and radiation resistance. Therefore, the preparation of boron nitride nanomaterials, the measurement of nanostructures, the assembly of nanodevices, the testing of boron nitride toughened ceramics and optical and electrical properties have become important research directions in the field of inorganic nanomaterials.more202111-22 -

.png) Aluminum Matrix Composites Reinforced by Titanium Diboride ParticlesAluminum matrix composites reinforced by titanium diboride particles have been widely used in aerospace, automotive, The fields of electronic packaging and military equipment, especially the large commercial aircraft (C919) have broad application prospects. The domestic generally adopts silicon carbide (SiC) particle enhancement, but foreign countries tend to adopt titanium diboride (TiB2) particle enhancement because Titanium diboride phase and aluminum alloy have better wettability. Boeing of the United States and Airbus of Europe should be in the process of testing a large number of samples.more202111-11

Aluminum Matrix Composites Reinforced by Titanium Diboride ParticlesAluminum matrix composites reinforced by titanium diboride particles have been widely used in aerospace, automotive, The fields of electronic packaging and military equipment, especially the large commercial aircraft (C919) have broad application prospects. The domestic generally adopts silicon carbide (SiC) particle enhancement, but foreign countries tend to adopt titanium diboride (TiB2) particle enhancement because Titanium diboride phase and aluminum alloy have better wettability. Boeing of the United States and Airbus of Europe should be in the process of testing a large number of samples.more202111-11