news center

-

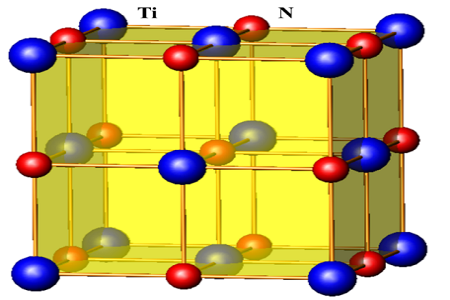

Preparation of titanium nitride(TiN)Titanium nitride has good physical and chemical properties such as high melting point, good chemical stability, high hardness, good electrical conductivity, thermal conductivity and optical properties, making it very important in various fields, especially in the field of new cermets and decorations. aspect. The industry's demand for titanium nitride powder is increasing. Titanium nitride as a coating is inexpensive, wear-resistant and corrosion-resistant, and its many properties are better than vacuum coatings. This article introduced the common preparation methods of titanium nitride.more202111-09

Preparation of titanium nitride(TiN)Titanium nitride has good physical and chemical properties such as high melting point, good chemical stability, high hardness, good electrical conductivity, thermal conductivity and optical properties, making it very important in various fields, especially in the field of new cermets and decorations. aspect. The industry's demand for titanium nitride powder is increasing. Titanium nitride as a coating is inexpensive, wear-resistant and corrosion-resistant, and its many properties are better than vacuum coatings. This article introduced the common preparation methods of titanium nitride.more202111-09 -

.jpg) Influencing Factors of Preparation of Ultra-fine Zirconium Diboride PowdersDepending on the basic principle of carbothermal reduction, Ultra-fine zirconium diboride powders could be synthesized. In this study, the influence of the molar ratio of Zr4+ to citric acid, sol-gel temperature, the value of pH and content of dispersant on amorphous precursor of zirconium diboride and the synthesized powders were investigated. X-ray diffraction ( XRD) , infrared spectroscopy ( IR) , laser particle size analyzer, field emission scanning electron microscope ( FESEM) and transmission electron microscope (TEM) were used to characterize amorphous precursor zirconium diboride and synthesized powders. It was discovered that, the optimum condition of complexation is Zr4 + /citric acid molar ratio of 2 and the pH value of 4 ; when sol-gel temperature is 50 °C , the synthesized powders exhibited near- spherical morphology. Besides the disperse function, polyethylene glycol can also guide sol particles to reunite, this can result in the ordered arrangement of crystal particles by pyrolysis and the synthesized powders which have good homogeneity and dispersity,especially with polyethylene glycol content of 2%.more202111-05

Influencing Factors of Preparation of Ultra-fine Zirconium Diboride PowdersDepending on the basic principle of carbothermal reduction, Ultra-fine zirconium diboride powders could be synthesized. In this study, the influence of the molar ratio of Zr4+ to citric acid, sol-gel temperature, the value of pH and content of dispersant on amorphous precursor of zirconium diboride and the synthesized powders were investigated. X-ray diffraction ( XRD) , infrared spectroscopy ( IR) , laser particle size analyzer, field emission scanning electron microscope ( FESEM) and transmission electron microscope (TEM) were used to characterize amorphous precursor zirconium diboride and synthesized powders. It was discovered that, the optimum condition of complexation is Zr4 + /citric acid molar ratio of 2 and the pH value of 4 ; when sol-gel temperature is 50 °C , the synthesized powders exhibited near- spherical morphology. Besides the disperse function, polyethylene glycol can also guide sol particles to reunite, this can result in the ordered arrangement of crystal particles by pyrolysis and the synthesized powders which have good homogeneity and dispersity,especially with polyethylene glycol content of 2%.more202111-05 -

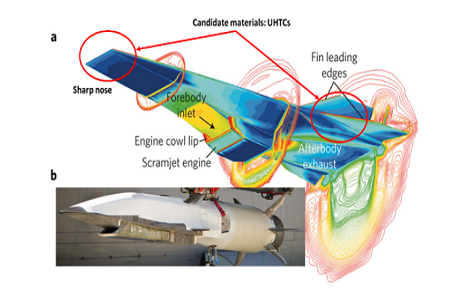

Comparison of different sintering methods of ZrC (zirconium carbide) ceramics and analysis of their application performanceZrC ceramic materials have high melting point, low density and wear resistance. Excellent temperature resistance and oxidation and ablation resistance, it can be used in the service environment of hypersonic aircraft nose cones, wing leading edges and aviation ramjet nozzles. It can be regarded as one of the candidate materials for the extreme thermal components of hypersonic aircraft and has received widespread attention .At present, the research on ZrC ceramic materials mainly focuses on improving the sintering performance of ZrC ceramic materials, low-temperature oxidation resistance and improving the fracture toughness of the materials.more202110-25

Comparison of different sintering methods of ZrC (zirconium carbide) ceramics and analysis of their application performanceZrC ceramic materials have high melting point, low density and wear resistance. Excellent temperature resistance and oxidation and ablation resistance, it can be used in the service environment of hypersonic aircraft nose cones, wing leading edges and aviation ramjet nozzles. It can be regarded as one of the candidate materials for the extreme thermal components of hypersonic aircraft and has received widespread attention .At present, the research on ZrC ceramic materials mainly focuses on improving the sintering performance of ZrC ceramic materials, low-temperature oxidation resistance and improving the fracture toughness of the materials.more202110-25 -

.png) What high-value potential applications does titanium carbide have after nanometerization?At present, the research on titanium carbide mainly focuses on the preparation and application of ultra-thin nanosheets.

What high-value potential applications does titanium carbide have after nanometerization?At present, the research on titanium carbide mainly focuses on the preparation and application of ultra-thin nanosheets.

Nano-titanium carbide powder (nano-TiC powder)is used in spraying materials, welding materials, hard film materials, military aviation materials, cemented carbide and cermets.

One-dimensional nanomaterials derived from titanium carbide starting materials have become the main research direction, including titanium carbide (Ti3C2) nanobelts, titanate nanobelts and titanium dioxide (TiO2) nanowires.more202110-18 -

(1).png) Ultra-high temperature ceramics help high-speed aircraft withstand the high temperature of 2000 ℃!The ultra-high-speed wind tunnel provides the necessary conditions for the high-speed flight of the aircraft, but because the surface temperature of the high-speed aircraft body increases with the increase of speed, it can often reach 2000 ℃ or even 3000 ℃ during high-speed flight. Performance presents a serious challenge.more202110-08

Ultra-high temperature ceramics help high-speed aircraft withstand the high temperature of 2000 ℃!The ultra-high-speed wind tunnel provides the necessary conditions for the high-speed flight of the aircraft, but because the surface temperature of the high-speed aircraft body increases with the increase of speed, it can often reach 2000 ℃ or even 3000 ℃ during high-speed flight. Performance presents a serious challenge.more202110-08