Effect of ZrC-doping on Microstructural and Mechanical Properties of ZTA Ceramic Composites

ZTA is a new type of composite ceramic material with alumina (Al2O3) as the matrix and partially stabilized zirconia (ZrO2) as the reinforcing and toughening phase. Studies have shown that the mechanical properties of ZTA ceramics are between Al2O3 ceramics and ZrO2 ceramics. It not only shows the high toughness and high strength of ZrO2 ceramics, but also retains the advantages of Al2O3 ceramics’ high hardness, and the price is lower than that of ZrO2 ceramics. Oxidation The main mechanism of zirconium toughened alumina is: when the temperature is reduced to about 1 000 ℃, the martensitic transformation of tetragonal ZrO2 into monoclinic ZrO2 occurs, accompanied by 3% to 5% volume expansion and 8% shear Shear strain, the shear stress and volume expansion of the phase change particles produce compressive strain on the matrix, which leads to the closure of microcracks, which requires more energy for crack propagation, thereby improving the fracture toughness of the material. Because ZTA composite ceramics have excellent high temperature resistance, corrosion resistance, thermal shock resistance, strength, toughness, and biocompatibility, they are used in various fields such as advanced nuclear energy materials, ceramic tools, wear-resistant components, and biomedical applications.

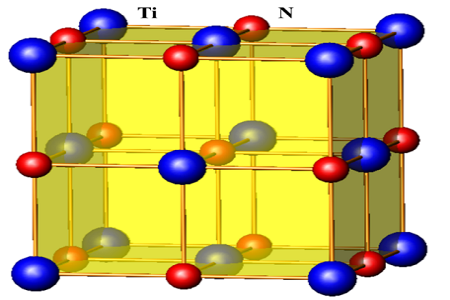

Toughening through zirconia phase transformation has improved the brittleness of ceramics to a certain extent, but the comprehensive properties of this single-phase strengthened and toughened ZTA composite ceramics still cannot meet the needs of many special industries. For example, near-space vehicles must be used in extreme environments above 2 000 ℃, and the high temperature resistance and ablation resistance of existing ceramic matrix composite materials cannot meet the requirements; the application of ceramic materials in new nuclear reactors is due to their toughness. Poor, low thermal conductivity, etc. are limited. The use of multi-component synergistic strengthening and coupling of multiple toughening mechanisms has become an important research direction to improve the mechanical properties of ZTA ceramics. In addition, the multi-component modulation provides an important research method for the improvement of the comprehensive properties of composite ceramics such as thermal, friction, and wear. At present, there are many studies on ZTA as a matrix, doped with SiC, TiC , TiO2 and other composite ceramics, but there are relatively few studies on doped ZrC. As a typical refractory metal compound (melting point: 3 540 ℃), ZrC has better high temperature resistance, ablation resistance, and radiation resistance than other ceramics.

Conclusion

In this work, the spark plasma sintering (SPS) method is used, and different contents of ZrC are added to the ZTA matrix to study the effect of ZrC doping on the microstructure and mechanical properties of ZTA composite ceramics.

There is no impurity phase in the multiphase ceramics, and the chemical compatibility between the components is good. The size of each crystal grain is uniform, and there is no abnormal growth phenomenon, and its fracture mode is the coexistence of intergranular fracture and transgranular fracture. With the increase of ZrC content, the bending strength first increased from 675 MPa to 722 MPa, and then decreased to 605 MPa, which is caused by the different dislocation density, stress, and porosity of the composite ceramics with different ZrC content. Due to the coexistence of intergranular fracture and transgranular fracture, stress-induced phase transition and other toughening mechanisms, the fracture toughness of the composite ceramic increases monotonically with the increase of ZrC content, from 5.47 MPa·m1/2 to 6.51 MPa·m1/2. The maximum hardness is 17.30 GPa, with the increase of ZrC content, the hardness gradually decreases to 16.19 GPa, which is caused by the difference in sample density and inter-grain distortion energy under different ZrC doping levels.

Toughening through zirconia phase transformation has improved the brittleness of ceramics to a certain extent, but the comprehensive properties of this single-phase strengthened and toughened ZTA composite ceramics still cannot meet the needs of many special industries. For example, near-space vehicles must be used in extreme environments above 2 000 ℃, and the high temperature resistance and ablation resistance of existing ceramic matrix composite materials cannot meet the requirements; the application of ceramic materials in new nuclear reactors is due to their toughness. Poor, low thermal conductivity, etc. are limited. The use of multi-component synergistic strengthening and coupling of multiple toughening mechanisms has become an important research direction to improve the mechanical properties of ZTA ceramics. In addition, the multi-component modulation provides an important research method for the improvement of the comprehensive properties of composite ceramics such as thermal, friction, and wear. At present, there are many studies on ZTA as a matrix, doped with SiC, TiC , TiO2 and other composite ceramics, but there are relatively few studies on doped ZrC. As a typical refractory metal compound (melting point: 3 540 ℃), ZrC has better high temperature resistance, ablation resistance, and radiation resistance than other ceramics.

Conclusion

In this work, the spark plasma sintering (SPS) method is used, and different contents of ZrC are added to the ZTA matrix to study the effect of ZrC doping on the microstructure and mechanical properties of ZTA composite ceramics.

There is no impurity phase in the multiphase ceramics, and the chemical compatibility between the components is good. The size of each crystal grain is uniform, and there is no abnormal growth phenomenon, and its fracture mode is the coexistence of intergranular fracture and transgranular fracture. With the increase of ZrC content, the bending strength first increased from 675 MPa to 722 MPa, and then decreased to 605 MPa, which is caused by the different dislocation density, stress, and porosity of the composite ceramics with different ZrC content. Due to the coexistence of intergranular fracture and transgranular fracture, stress-induced phase transition and other toughening mechanisms, the fracture toughness of the composite ceramic increases monotonically with the increase of ZrC content, from 5.47 MPa·m1/2 to 6.51 MPa·m1/2. The maximum hardness is 17.30 GPa, with the increase of ZrC content, the hardness gradually decreases to 16.19 GPa, which is caused by the difference in sample density and inter-grain distortion energy under different ZrC doping levels.

.png)